Kaarboohaydrayt Madow oo Silikoon ah

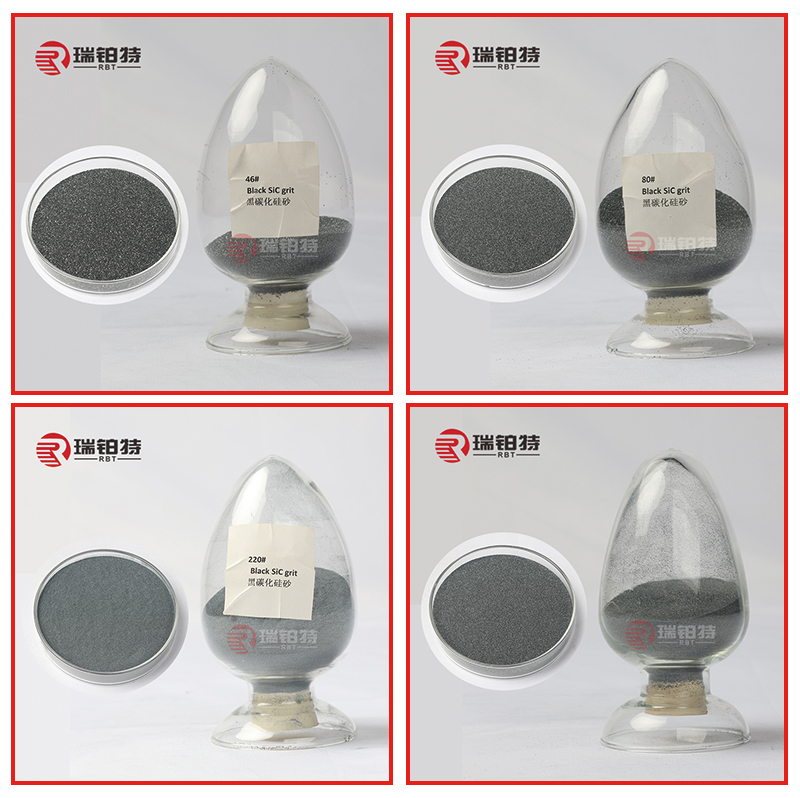

Macluumaadka Badeecada

Madow oo ah Silicon Carbide (SiC)waa macdan aad u adag (Mohs 9.1/ 2550 Knoop) oo laga sameeyay nin kaas oo leh kuleyl badan iyo xoog sare heerkulka sare (1000°C, SiC waa 7.5 jeer ka xoog badan Al203). SiC wuxuu leeyahay qaab dabacsanaan ah oo ah 410 GPa, iyada oo aan hoos u dhicin xoogga ilaa 1600°C, mana dhalaaliso cadaadiska caadiga ah laakiin waxay kala go'daa 2600°C.

Codsiyada:

Baloogyada carbide-ka ee silikoon madowwaxaa badanaa loo isticmaalaa codsiyada u baahan jarista, farsamaynta ama shiididda, sida diyaarinta giraangiraha shiididda, jarista saxannada, iwm.

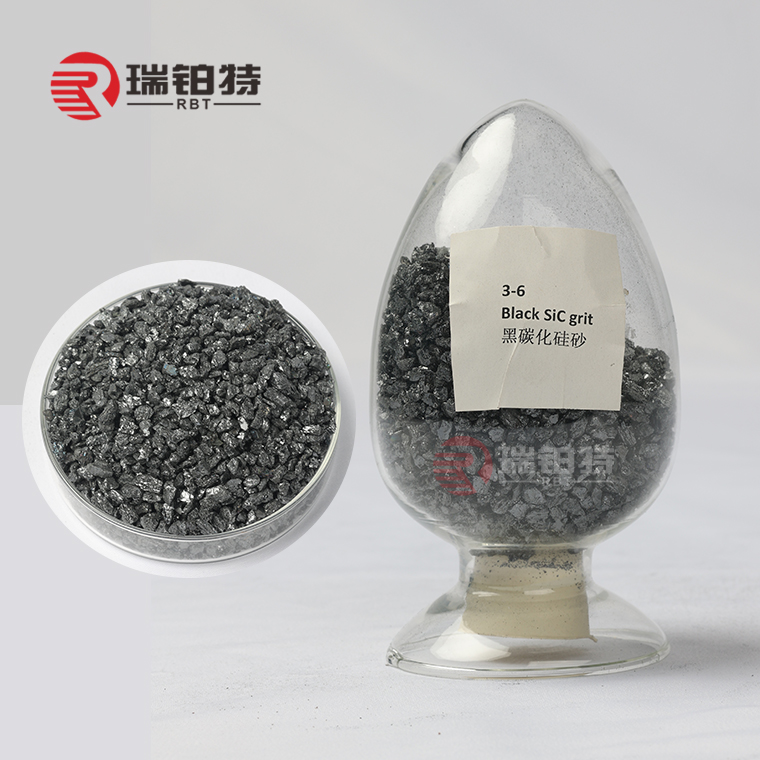

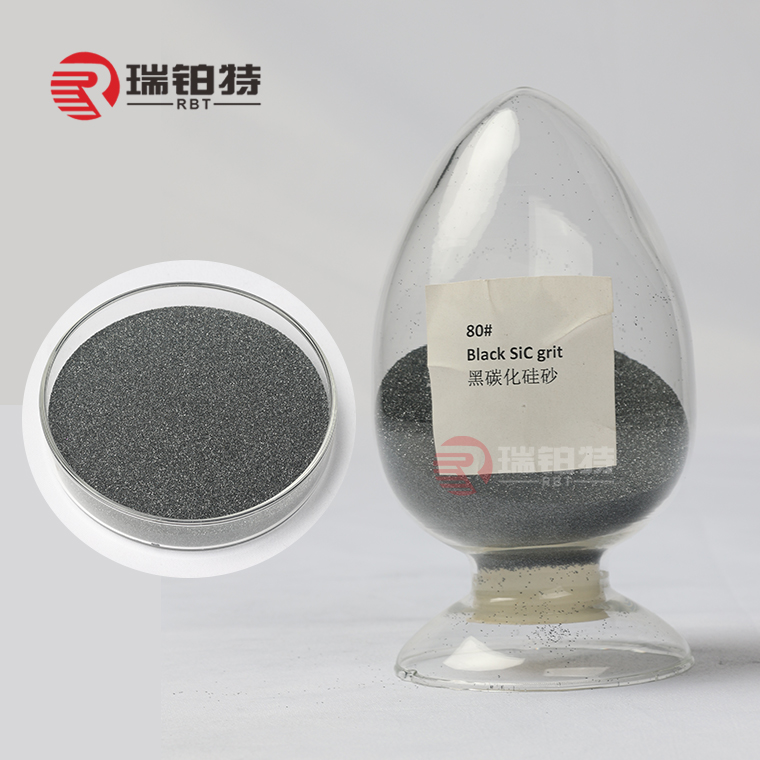

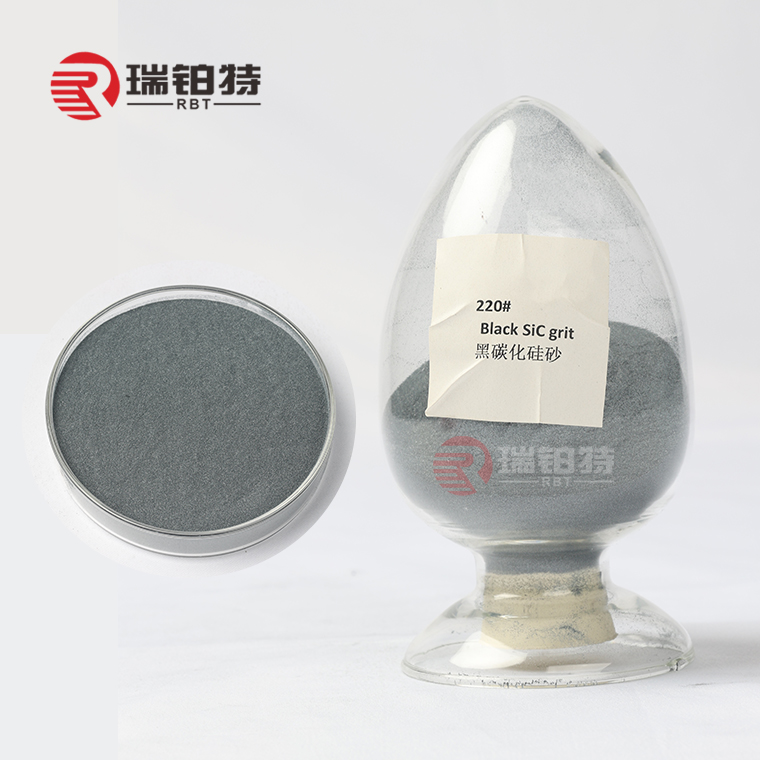

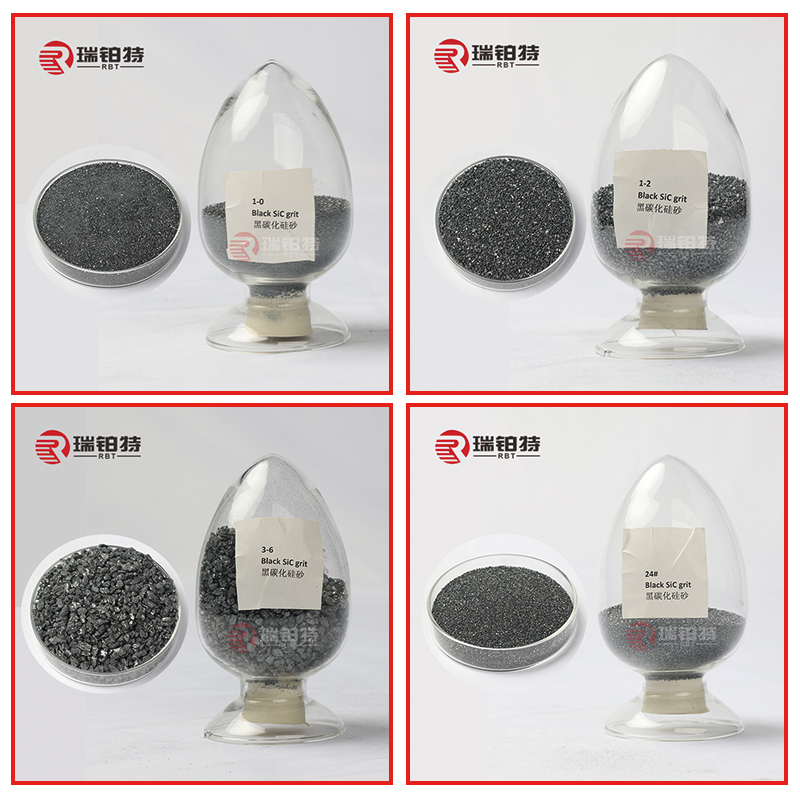

CabbirkaXarig madow oo silikoon ah oo carbide ahGuud ahaan waxay u dhaxaysaa dhowr millimitir ilaa tobanaan mikron. Waxaa badanaa loo isticmaalaa bacriminta ciidda, nadiifinta, daawaynta dusha sare iyo codsiyada kale si loo bixiyo dusha sare oo nadiif ah oo isku mid ah.

Cabbirka walxahaBudada carbide-ka ee silikoon madowGuud ahaan waa heerka nanometer ilaa micron. Badeecadaha budada ah waxaa badanaa loo isticmaalaa xoojinta agabka, dahaarka, buuxinta iyo codsiyada kale.

Sawirro Faahfaahin ah

Shaxda Isbarbardhigga Cabbirka Godadka

| Lambarka Grit. | Shiinaha GB2477-83 | Jabaan JISR 6001-87 | Mareykanka ANSI(76) | 欧洲磨料协FEPA(84) | 国际ISO(86) |

| 4 | 5600-4750 |

| 5600-4750 | 5600-4750 | 5600-4750 |

| 5 | 4750-4000 |

| 4750-4000 | 4750-4000 | 4750-4000 |

| 6 | 4000-3350 |

| 4000-3350 | 4000-3350 | 4000-3350 |

| 7 | 3350-2800 |

| 3350-2800 | 3350-2800 | 3350-2800 |

| 8 | 2800-2360 | 2800-2360 | 2800-2360 | 2800-2360 | 2800-2360 |

| 10 | 2360-2000 | 2360-2000 | 2360-2000 | 2360-2000 | 2360-2000 |

| 12 | 2000-1700 | 2000-1700 | 2000-1700 | 2000-1700 | 2000-1700 |

| 14 | 1700-1400 | 1700-1400 | 1700-1400 | 1700-1400 | 1700-1400 |

| 16 | 1400-1180 | 1400-1180 | 1400-1180 | 1400-1180 | 1400-1180 |

| 20 | 1180-1000 | 1180-1100 | 1180-1000 | 1180-1000 | 1180-1000 |

| 22 | 1000-850 | - | - | 1000-850 | 1000-850 |

| 24 | 850-710 | 850-710 | 850-710 | 850-710 | 850-710 |

| 30 | 710-600 | 710-600 | 710-600 | 710-600 | 710-600 |

| 36 | 600-500 | 600-500 | 600-500 | 600-500 | 600-500 |

| 40 | 500-425 | - | - | 500-425 | 500-425 |

| 46 | 425-355 | 425-355 | 425-355 | 425-355 | 425-355 |

| 54 | 355-300 | 355-300 | 355-297 | 355-300 | 355-300 |

| 60 | 300-250 | 300-250 | 297-250 | 300-250 | 300-250 |

| 70 | 250-212 | 250-212 | 250-212 | 250-212 | 250-212 |

| 80 | 212-180 | 212-180 | 212-180 | 212-180 | 212-180 |

| 90 | 180-150 | 180-150 | 180-150 | 180-150 | 180-150 |

| 100 | 150-125 | 150-125 | 150-125 | 150-125 | 150-125 |

| 120 | 125-106 | 125-106 | 125-106 | 125-106 | 125-106 |

| 150 | 106-75 | 106-75 | 106-75 | 106-75 | 106-75 |

| 180 | 90-63 | 90-63 | 90-63 | 90-63 | 90-63 |

| 220 | 75-53 | 75-53 | 75-53 | 75-53 | 75-53 |

| 240 | 75-53 | - | 75-53 | - |

Tusmada Badeecada

| Cabbirka Shabaqa | Halabuurka Kiimikada% (Miisaanka) | ||

| SIC | F·C | Fe2O3 | |

| 12#-90# | ≥98.50 | ≤0.20 | ≤0.60 |

| 100#-180# | ≥98.00 | ≤0.30 | ≤0.80 |

| 220#-240# | ≥97.00 | ≤0.30 | ≤1.20 |

| W63-W20 | ≥96.00 | ≤0.40 | ≤1.50 |

| W14-W5 | ≥93.00 | ≤0.40 | ≤1.70 |

Codsiga

Qalabka Baabi'inta iyo Shiididda:Iyada oo ay ugu wacan tahay adkaanteeda sare iyo adkaysigeeda gaarka ah, ciidda madow ee silicon carbide ayaa si weyn loogu isticmaalaa shiididda iyo nadiifinta muraayadda indhaha, carbide-ka sibidhka leh, birta titanium-ka, birta sibidhka, iyo afaynta qalabka birta xawaaraha sare leh. Waxa kale oo ay ku habboon tahay jarista iyo shiididda walxaha leh xoog jilicsan oo hooseeya, sida jarista silicon-ka keli ah iyo ulaha silicon-ka polycrystalline, shiididda wafer-ka silicon-ka keli ah, iwm.

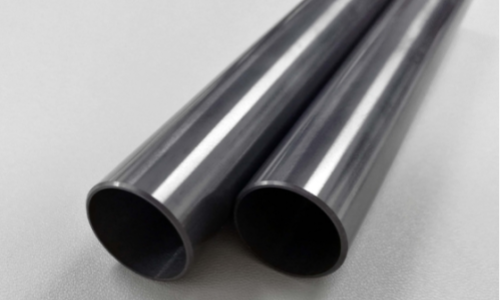

Agabka Adkeysiga leh:Warshadaha birta, ciidda madow ee silicon carbide waxaa badanaa loo isticmaalaa dahaarka, salka iyo balastarrada foornada heerkulka sare leh si loo hubiyo shaqada caadiga ah ee qalabka birta. Waxa kale oo laga sameeyaa walxo aan la qabsan karin, sida qaybaha foornada heerkulka sare leh iyo taageerooyinka, kuwaas oo u adkaysta shoogga kulaylka, cabbirkoodu yar yahay, miisaankoodu fudud yahay oo xooggiisu sarreeyo, waxayna leeyihiin saameyn wanaagsan oo lagu badbaadinayo tamarta.

Isticmaalka Kiimikada:Warshadaha kiimikada, ciid madow oo silicon carbide ah ayaa loo isticmaalaa in lagu soo saaro qalabka kiimikada u adkaysta daxalka, dhuumaha iyo waalka si loo hubiyo in qalabka si ammaan ah loogu shaqeeyo iyadoo la adeegsanayo warbaahinta daxalka iyo xaaladaha heerkulka sare. Intaa waxaa dheer, waxaa sidoo kale loo isticmaali karaa nadiifiye loogu talagalay dhalaalinta birta, taas oo ah, deoksaydheeye loogu talagalay sameynta birta iyo hagaajinta qaab-dhismeedka birta la shubay.

Warshadaha Elektarooniga:Warshadaha elektaroonigga, ciidda madow ee silicon carbide waxaa loo isticmaalaa in lagu sameeyo agabka semiconductor-ka iyo qaybaha elektaroonigga ah, sida aaladaha elektaroonigga ah ee awoodda sare leh, substrate-yada wareegga isku dhafan, iwm., si loo hubiyo waxqabadka sare iyo xasilloonida qalabka elektaroonigga ah.

Isticmaalka Kale:Ciidda carbide-ka ee madow ee silicon ayaa sidoo kale loo isticmaalaa in lagu sameeyo dhoobada shaqaynaysa, walxaha kulaylinta korontada, walxaha semiconductor-ka heerkulka sare leh, looxyada fog-infrared, walxaha waalka qabata hillaaca, iwm. Waxaa sidoo kale loo isticmaalaa in lagu sameeyo dahaarka digsiga ee aan dhegdheg lahayn, dahaarka u adkaysta xirashada, dahaarka ka hortagga daxalka, iwm.

Xirmada & Bakhaarka

| Xirmo | Bacda 25KG | Bacda 1000KG |

| Tirada | 24-25 Tan | 24 Tan |

Astaamaha Shirkadda

Shandong Robert New Material Co., Ltd.Waxay ku taal Magaalada Zibo, Gobolka Shandong, Shiinaha, oo ah saldhig wax soo saar agab oo aan la taaban karin. Waxaan nahay shirkad casri ah oo isku daraysa cilmi-baarista iyo horumarinta, wax soo saarka, iibinta, naqshadeynta foornada iyo dhismaha, tignoolajiyada, iyo agabka dibadda loo dhoofiyo. Waxaan leenahay qalab dhammaystiran, tignoolajiyada horumarsan, xoog farsamo oo xooggan, tayada badeecada oo aad u fiican, iyo sumcad wanaagsan. Warshadeennu waxay daboolaysaa in ka badan 200 oo acres, wax soo saarka sanadlaha ah ee agabka qaabaysan ee la taaban karo waa qiyaastii 30000 tan, agabka aan qaabaysanna waa 12000 tan.

Alaabtayada ugu muhiimsan ee agabka aan la qabsan karin waxaa ka mid ah:agabka alkaline-ka ee aan lahayn agabka aluminium silicon; agabka aan lahayn qaab-dhismeed; agabka kulaylka ee aan lahayn agabka dahaarka; agabka gaarka ah ee aan lahayn agabka; agabka shaqayn kara ee loogu talagalay nidaamyada shubka joogtada ah.

Su'aalaha Badiya La Weydiiyo

Ma u baahan tahay caawimo? Hubi inaad booqato golayaashayada taageerada si aad u hesho jawaabaha su'aalahaaga!

Waxaan nahay soo-saare dhab ah, warshadeenu waxay ku takhasustay soo saarista agabyada aan la qabsan karin in ka badan 30 sano. Waxaan ballan qaadaynaa inaan bixinno qiimaha ugu fiican, adeegga ugu fiican ee iibka kahor iyo adeegga iibka kadib.

Nidaam kasta oo wax soo saar ah, RBT waxay leedahay nidaam QC oo dhammaystiran oo loogu talagalay halabuurka kiimikada iyo sifooyinka jireed. Waxaanan tijaabin doonnaa alaabta, shahaadada tayadana waxaa lala soo raaci doonaa alaabta. Haddii aad leedahay shuruudo gaar ah, waxaan isku dayi doonnaa sida ugu wanaagsan ee aan u dabooli karno.

Iyadoo ku xiran tirada, waqtiga keenisteenu wuu ka duwan yahay. Laakiin waxaan ballan qaadaynaa inaan sida ugu dhakhsaha badan u soo dirno iyadoo tayo la hubo la hubo.

Dabcan, waxaan bixinaa muunado bilaash ah.

Haa, dabcan, waa lagu soo dhaweynayaa inaad booqato shirkadda RBT iyo alaabtayada.

Ma jiro xad, waxaan ku siin karnaa talada iyo xalka ugu fiican iyadoo loo eegayo xaaladdaada.

Waxaan samaynaynay agab aan la qabsan karin in ka badan 30 sano, waxaan leenahay taageero farsamo oo xooggan iyo waayo-aragnimo qani ah, waxaan ka caawin karnaa macaamiisha inay naqshadeeyaan foosto kala duwan oo ay bixiyaan adeeg hal joogsi ah.