Hoobiye Premium ah oo loogu talagalay Isku-xidhka Heerkulka Sare

Sharaxaada

Kala soocidda

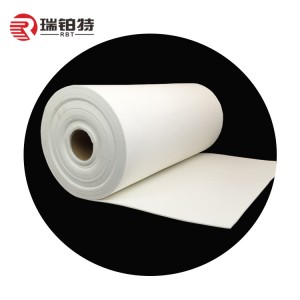

Madaafiicda refractory, oo sidoo kale loo yaqaan hoobiye dabka ama walxaha wadajirka ah (budada), oo loo isticmaalo sida isku xidhka alaabada refractory maaddooyinka lebenka, sida ku cad walxaha waxaa loo qaybin karaa dhoobo, aluminium sare, silikoon iyo hoobiyeyaasha magnesium, iwm.

Waxaa loo yaqaan hoobiye dib-u-celinta caadiga ah oo laga sameeyay budada clinker-ka-celinta iyo dhoobada caagga ah sida xiraha iyo wakiilka caagga ah.Xooggeeda heerkulka qolka waa hooseeyaa, iyo samaynta isku-xidhka dhoobada ee heerkulka sare ayaa leh awood sare.

Iyada oo leh hydraulicity, hawo engegnaanta ama qalabka kulayl-adag sida xidhe, loo yaqaan kiimikaad ku xidhka hoobiye refractory, sida ka hooseeya samaynta heerkulka xidhitaanka dhoobada ka hor wax soo saarka ee falcelin kiimikaad gaar ah iyo qallafsanaan.

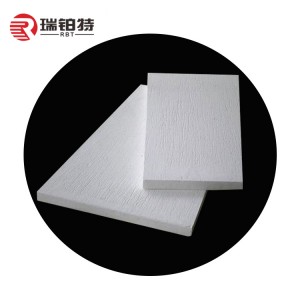

Astaamaha

Sifooyinka hoobiyeyaasha refractory: caag wanaagsan, dhismo ku habboon;xoogga dammaanadda sare, iska caabin daxalka xooggan;refractority sare, ilaa 1650 ± 50 ℃;iska caabin weerar oo wanaagsan;hantida spalling kulaylka wanaagsan.

Codsiga

Hoobiyaha refractory waxaa inta badan loo isticmaalaa foornada kookaha, foornada dhalada, foornada qaraxa, kariyaha kulul, biraha, warshadaha walxaha dhismaha, mashiinada, kiimikaalka batroolka, dhalooyinka, kuleyliyaha, korontada, birta iyo birta, sibidhka iyo foornada kale ee warshadaha.

Tusmada Alaabta

| INDEX | dhoobo | Aluminium sare | Corundum | Silica | Magnesium | dhoobo khafiif ah | |||||||

| RBT MN -42 | RBT MN -45 | RBT MN -55 | RBT MN -65 | RBT MN -75 | RBT MN -85 | RBT MN -90 | RBT GM -90 | RBT MF -92 | RBT MF -95 | RBT MF -97 | RBT MM -50 | ||

| Refractoriness (℃) | 1700 | 1700 | 1720kii | 1720kii | 1750kii | 1800 | 1820kii | 1670kii | 1790kii | 1790kii | 1820kii |

| |

| CCS/MOR (MPa) ≥ | 110℃×24h | 1.0 | 1.0 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | 1.0 | 1.0 | 1.0 | 1.0 | 0.5 |

| 1400℃×3h | 3.0 | 3.0 | 4.0 | 4.0 | 4.0 | 3.5 | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | 1.0 | |

| Waqtiga xidhitaanka (min) | 1 ~ 2 | 1 ~ 2 | 1 ~ 2 | 1 ~ 2 | 1 ~ 2 | 1 ~ 3 | 1 ~ 3 | 1 ~ 2 | 1 ~ 3 | 1 ~ 3 | 1 ~ 3 | 1 ~ 2 | |

| Al2O3%) ≥ | 42 | 45 | 55 | 65 | 75 | 85 | 90 | - | - | - | - | 50 | |

| SiO2 (%) ≥ | - | - | - | - | - | - | - | 90 | - | - | - | - | |

| MgO(%) ≥ | - | - | - | - | - | - | - | - | 92 | 95 | 97 | - | |