Alwaax Silikoon Carbide ah

Macluumaadka Badeecada

RBSiC/SiSiC Alwaaxwaxaa inta badan laga sameeyaa walxaha SiC iyo silicon dioxide iyo walxo kale oo lagu sifeeyay heerkul ah 1400-1500℃. Halabuurka waxaa ka mid ah walxaha SiC oo ah isku-darka iyo SiO2 oo ah marxaladda ugu weyn ee isku xidhka, waxayna leedahay astaamo xoog sare leh, iska caabin oksaydh wanaagsan iyo iska caabin shoogga kulaylka.

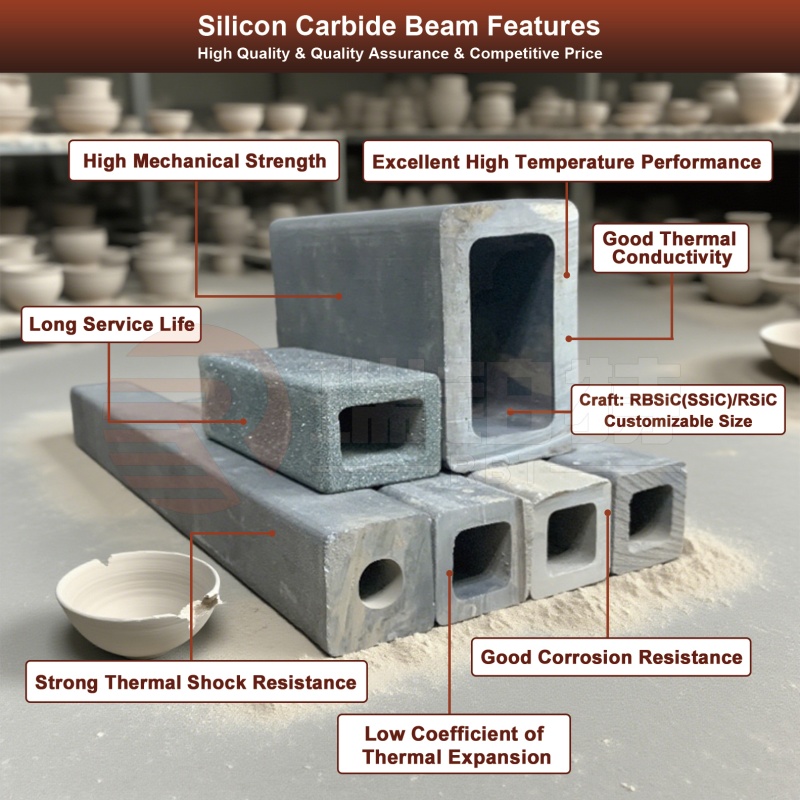

Astaamaha:

1. Awoodda qaadida heerkulka sare

2. Xasiloonida cabbirka

3. Ka-hortagga oksaydheynta iyo nabaad-guurka

4. U adkaysta qaboojinta iyo kululaynta degdegga ah

5. Xoog sare iyo iska caabin cadaadis

Laydhka RSiCwaa walax dhoobo ah oo tayo sare leh oo leh sifooyin aad u fiican sida xoog sare, adkeysi sare, iyo iska caabin heerkul sare. Hawsheeda wax soo saarku waxay inta badan ka kooban tahay laba tallaabo: marka hore, budada carbide-ka silicon-ka sifeynaysa jirka cagaaran ee xaaladaha heerkulka sare, ka dibna dib u habeynaysa iyada oo loo marayo daaweynta kulaylka falgalka si loo sameeyo walax dhoobo ah oo silicon carbide ah, ka dibna jarjar oo shiidi qaabka loo baahan yahay.

Astaamaha:

1. Xoog sare iyo adkaansho

2. Iska caabin wanaagsan oo kiimiko ah

3. Xasillooni heer sare ah oo heer sare ah

4. Isugeynta ballaarinta kulaylka oo aad u hooseysa

5. Qaboojinta kulaylka heerkulka sare oo heer sare ah oo heer sare ah

Tusmada Badeecada

| Falcelinta Sintering Silicon Carbide Beam | ||

| Shay | Cutubka | Xogta |

| Heerkulka ugu Badan ee Codsiga | ℃ | ≤1380 |

| Cufnaanta | g/cm3 | >3.02 |

| Fosfooraska Furan | % | ≤0.1 |

| Xoog Laabista | Mpa | 250(20℃); 280(1200℃) |

| Modulus of Elastictiy | GPA | 330(20℃); 300(1200℃) |

| Qaboojinta Kulaylka | W/mk | 45 (1200℃) |

| Isugeynta Ballaarinta Kulaylka | K-1*10-6 | 4.5 |

| Adkaanta Moh | | 9.15 |

| Aashitada Alkaline-ka-xaqiijin | | Aad u fiican |

| Awoodda qaadidda ee alwaaxyada RBSiC (SiSiC) | ||||||

| Cabbirka Qaybta (mm) | Derbiga Dhumucda (mm) | Rarista Xooggan (kg.m/L) | Rarista Si Isku Mid ah Loo Qaybiyay (kg.m/L) | |||

| Dhinaca B | Dhinaca H | Dhinaca W | Dhinaca H | Dhinaca W | Dhinaca H | |

| 30 | 30 | 5 | 74 | 74 | 147 | 147 |

| 30 | 40 | 5 | 117 | 95 | 235 | 190 |

| 40 | 40 | 6 | 149 | 149 | 298 | 298 |

| 50 | 50 | 6 | 283 | 283 | 567 | 567 |

| 50 | 60 | 6 | 374 | 331 | 748 | 662 |

| 50 | 70 | 6 | 473 | 379 | 946 | 757 |

| 60 | 60 | 7 | 481 | 481 | 962 | 962 |

| 80 | 80 | 7 | 935 | 935 | 1869 | 1869 |

| 100 | 100 | 8 | 1708 | 1708 | 3416 | 3416 |

| 110 | 110 | 10 | 2498 | 2498 | 4997 | 4997 |

Meelaha Codsiga ee RBSiC/SiSiC:

1. Foornooyinka warshadaha: Si ballaaran ayaa loogu isticmaalaa foornooyinka tunnelka, foornooyinka basaska, foornooyinka duubista ee lakabka labanlaabka ah iyo kuwa kaleQaab-dhismeedka culeyska qaada ee foornada warshadaha.

2. Warshadaha foornada korontada: Warshadaha foornada korontada, alwaaxyada silikoon carbide ayaa si weyn loo isticmaalaa sababtoo ah awooddooda qaadista heerkulka sare ee sare iyo cimri dhererkooda.

3. Soo saarista dhoobada: Soo saarista dhoobada maalinlaha ah iyo foornada nadaafadda, alwaaxyada silikoon carbide ayaa sidoo kale ah agabyada alaabta guriga ee foornada ku habboon.

Rinjiyada RSiC si weyn ayaa loogu isticmaalaa meelo badan, oo ay ku jiraan:?

1. Warshadaha dhoobada: waxaa loo isticmaalaa in lagu soo saaro agabka foornada heerkulka sare leh, agabka iska caabiya, iwm.

2. Hawada Sare: waxaa loo isticmaalaa qaybo ahaan, oo ku habboon heerkulka sare, cadaadiska sare iyo deegaannada wasakhowga hawada ee daran.

3. Injineernimada nukliyeerka: waxaa loo isticmaalaa walxaha shidaalka ee warshadaha tamarta nukliyeerka sababtoo ah sifooyinkeeda kiimikada ee deggan iyo xoogga heerkulka sare.

4. Korontada, birta, warshadaha kiimikada: waxaa loo isticmaalaa in lagu sameeyo waalka, walxaha bamka lagu shubo, daabyada marawaxadaha iyo qaybaha kale.

Astaamaha Shirkadda

Shandong Robert New Material Co., Ltd.waxay ku taal Magaalada Zibo, Gobolka Shandong, Shiinaha, kaas oo ah saldhig wax soo saar agab oo aan la isku halleyn karin. Waxaan nahay shirkad casri ah oo isku daraysa cilmi-baarista iyo horumarinta, wax soo saarka, iibinta, naqshadeynta iyo dhismaha foornada, tiknoolajiyada, iyo agabka aan la isku halleyn karin ee dhoofinta. Waxaan haynaa qalab dhammaystiran, tignoolajiyad horumarsan, xoog farsamo oo xooggan, tayo alaab oo aad u wanaagsan, iyo sumcad wanaagsan.Warshadeennu waxay daboolaysaa in ka badan 200 oo acres, wax soo saarka sanadlaha ah ee agabka qaabaysan ee qaloocan waa qiyaastii 30000 tan, agabka aan qaabaysanna waa 12000 tan.

Su'aalaha Badiya La Weydiiyo

Ma u baahan tahay caawimo? Hubi inaad booqato golayaashayada taageerada si aad u hesho jawaabaha su'aalahaaga!

Waxaan nahay soo-saare dhab ah, warshadeenu waxay ku takhasustay soo saarista agabyada aan la qabsan karin in ka badan 30 sano. Waxaan ballan qaadaynaa inaan bixinno qiimaha ugu fiican, adeegga ugu fiican ee iibka kahor iyo adeegga iibka kadib.

Nidaam kasta oo wax soo saar ah, RBT waxay leedahay nidaam QC oo dhammaystiran oo loogu talagalay halabuurka kiimikada iyo sifooyinka jireed. Waxaanan tijaabin doonnaa alaabta, shahaadada tayadana waxaa lala soo raaci doonaa alaabta. Haddii aad leedahay shuruudo gaar ah, waxaan isku dayi doonnaa sida ugu wanaagsan ee aan u dabooli karno.

Iyadoo ku xiran tirada, waqtiga keenisteenu wuu ka duwan yahay. Laakiin waxaan ballan qaadaynaa inaan sida ugu dhakhsaha badan u soo dirno iyadoo tayo la hubo la hubo.

Dabcan, waxaan bixinaa muunado bilaash ah.

Haa, dabcan, waa lagu soo dhaweynayaa inaad booqato shirkadda RBT iyo alaabtayada.

Ma jiro xad, waxaan ku siin karnaa talada iyo xalka ugu fiican iyadoo loo eegayo xaaladdaada.

Waxaan samaynaynay agab aan la qabsan karin in ka badan 30 sano, waxaan leenahay taageero farsamo oo xooggan iyo waayo-aragnimo qani ah, waxaan ka caawin karnaa macaamiisha inay naqshadeeyaan foosto kala duwan oo ay bixiyaan adeeg hal joogsi ah.