Tubooyinka qaboojinta Silicon Carbide

Qaybaha Alaabta

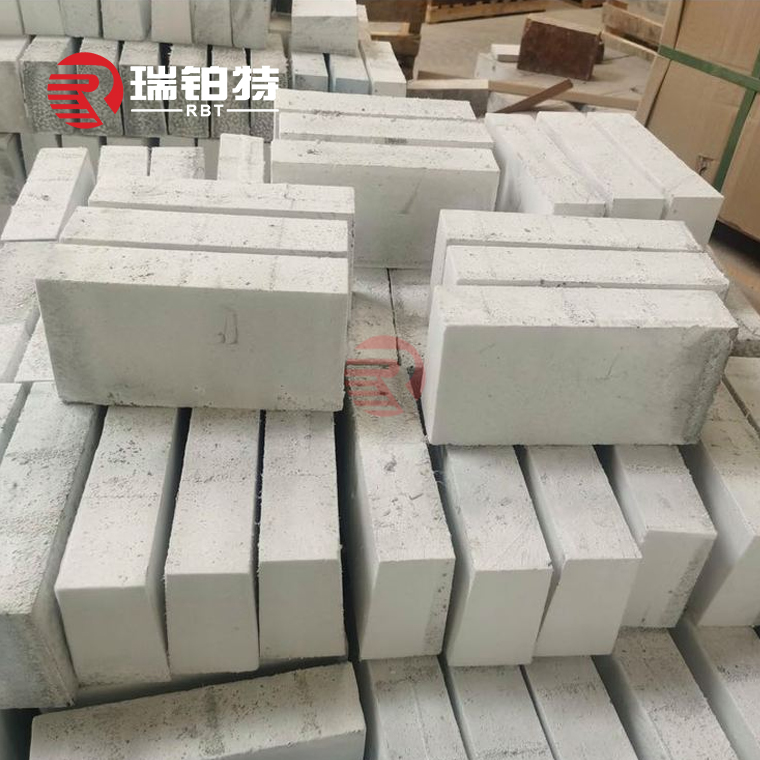

1. Ka falcelinta alaabada silikoon kaarbiide (RBSiC Products)

Reaction bonded silicon carbide (RBSiC) waa shay dhoobada injineernimada horumarsan oo soo saara wejiga isku xidhka silikoon carbide iyadoo ka falcelinaysa kaarboon bilaash ah oo leh silikon dareere ah oo hoos yimaada xaaladaha heerkulka sare. Qaybaheeda aasaasiga ah waxaa ka mid ah silikoon carbide (SiC) matrix iyo silikoon bilaash ah (Si). Kii hore wuxuu bixiyaa sifooyin farsamo oo aad u fiican, xirashada caabbinta iyo xasilloonida heerkulka sare,

halka kan dambe uu buuxiyo daloolada u dhexeeya qaybaha silikoon carbide si kor loogu qaado cufnaanta iyo sharafta qaab dhismeedka maaddada.

(1) Astaamaha:

Dejinta heerkulka sare:Heerkulka ugu sarreeya ee shaqeynaya 1350 ℃.

Xiro iska caabbinta iyo iska caabinta daxalka:Ku haboon xaaladaha shaqada adag ee heerkulka sare, aashitada, alkali iyo birta dhalaalaysa. ?

Kordhinta kulaylka sare iyo isku xidhka fidinta kulaylka hoose:Heerkulka kulaylku wuxuu u sarreeyaa ilaa 120-200 W/(m·K), iyo isku xidhka ballaadhinta kulaylku waa 4.5 × 10⁻ K⁻¹, kaas oo si wax ku ool ah uga hortagaya dillaaca kulaylka iyo daalka kulaylka. ?

Anti-oxidation:Lakabka difaaca cufan ee silica ayaa ka abuurma dusha sare heerkul sarreeya si loo kordhiyo nolosha adeegga.

(2) Alaabta ugu muhiimsan:

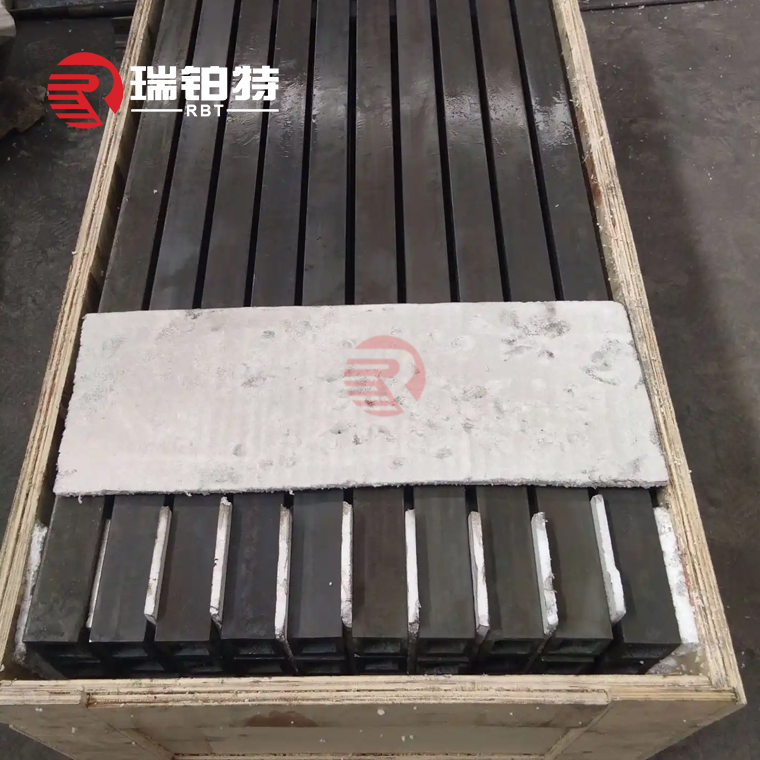

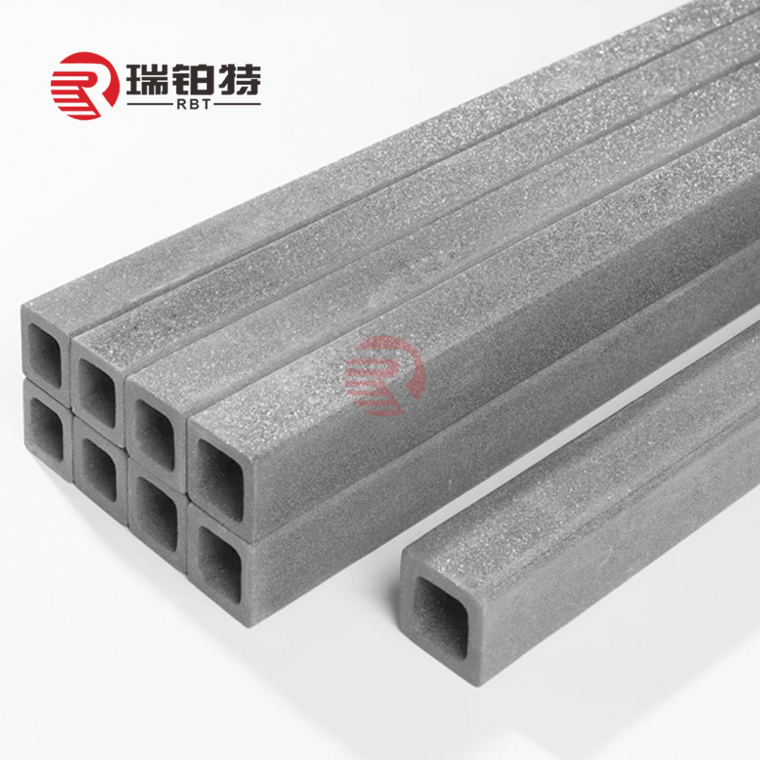

?Silicon carbide beam:loo isticmaalo qaab-dhismeedka rarka ee foornooyinka tunnel-ka, weelka-shuttle-ka iyo kilnnada kale ee warshadaha, oo leh iska caabin heerkul sare oo heersare ah.

?

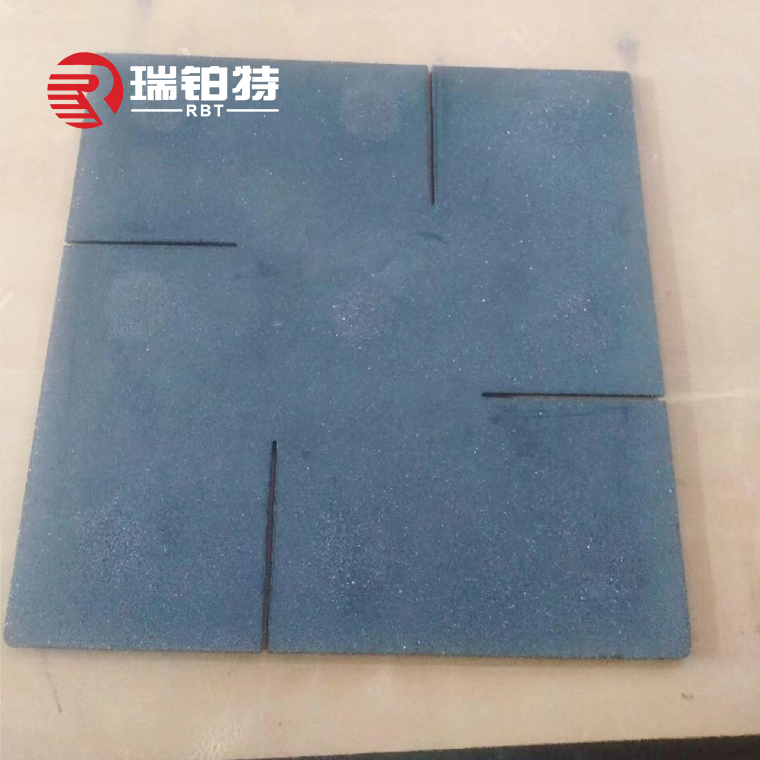

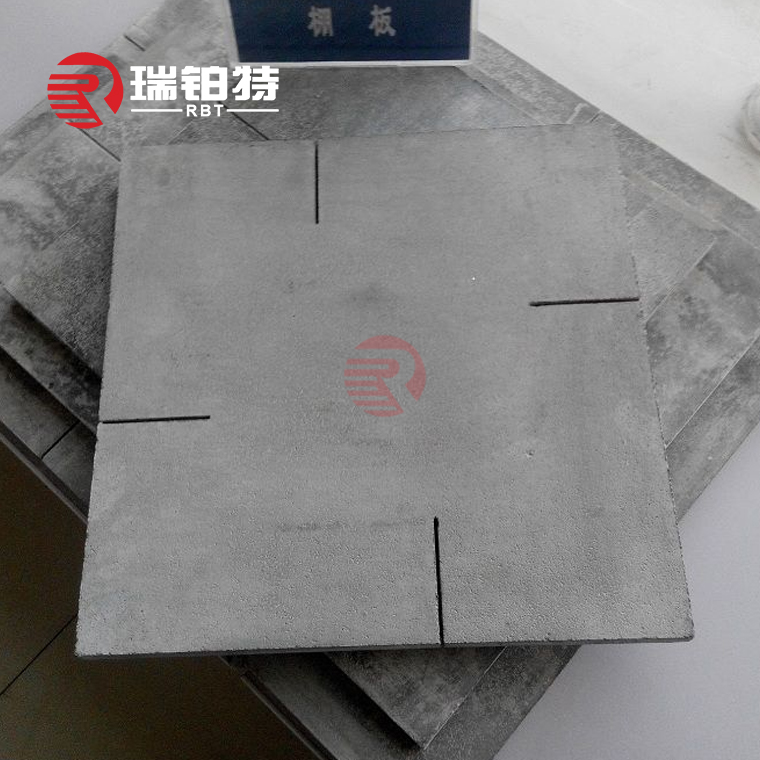

Silicon carbide saxan:loo isticmaalo walxaha dib-u-celinta ee kilns, oo leh sifooyinka isku xidhka oksaydhka. ?

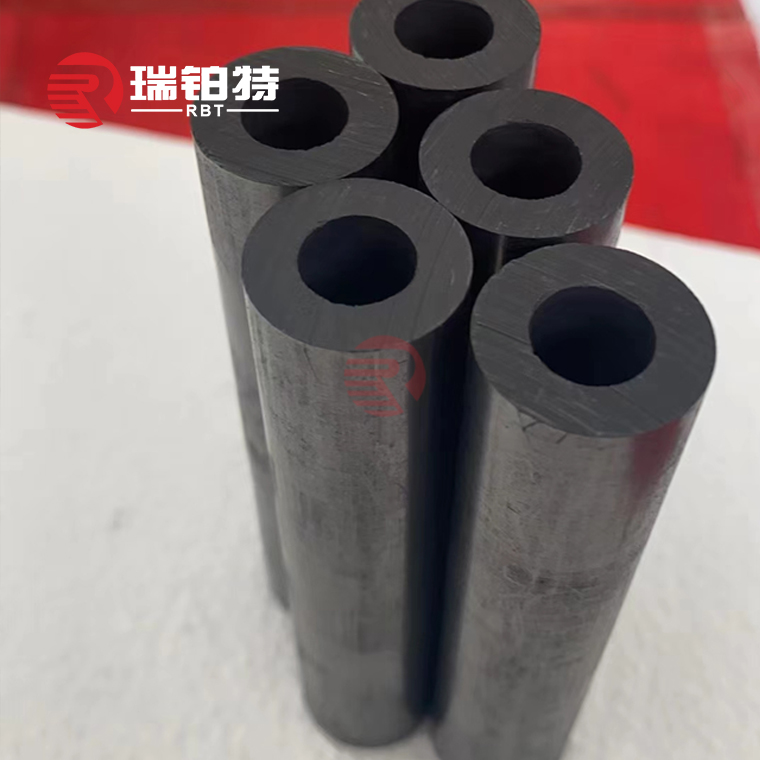

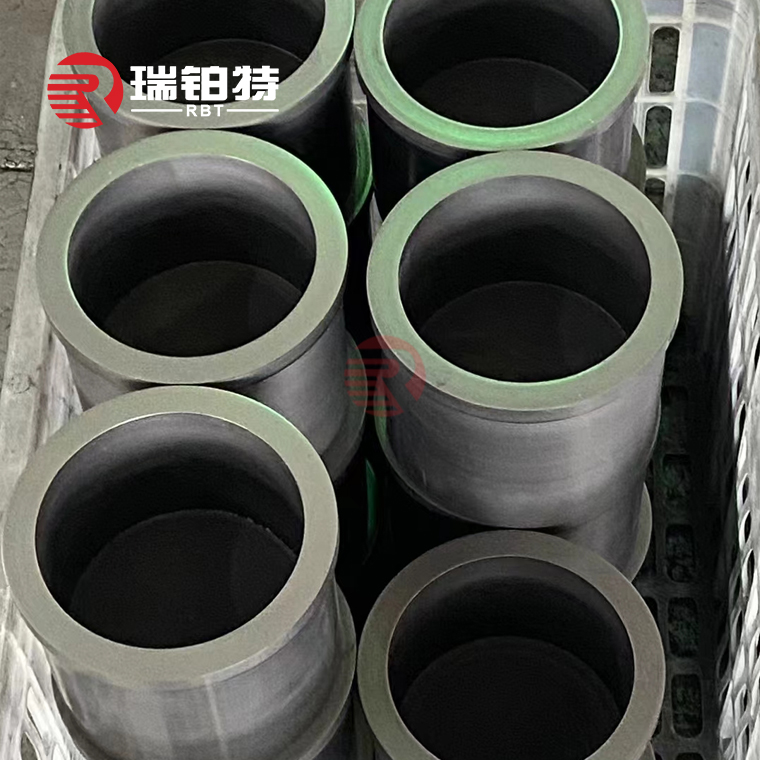

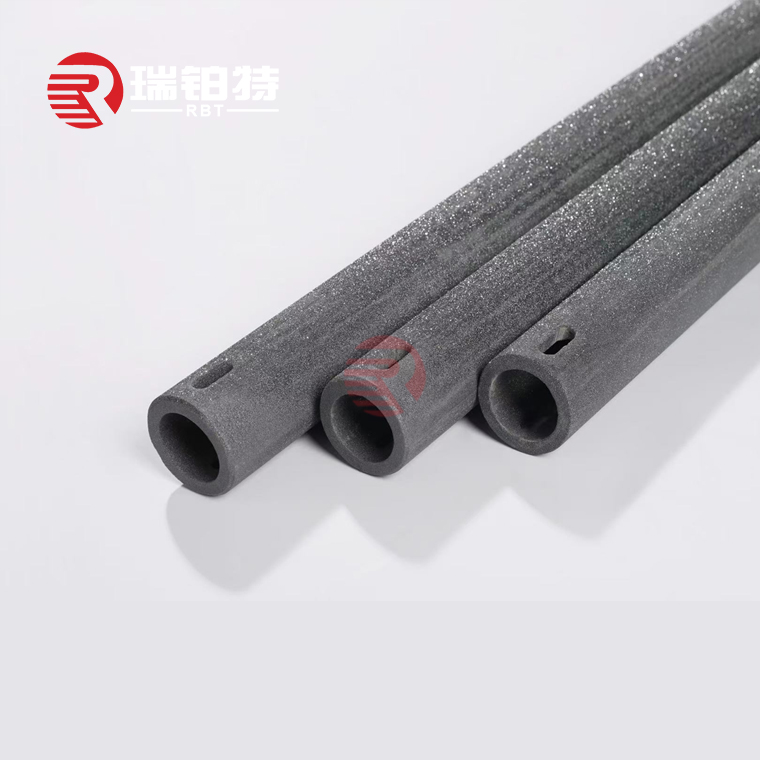

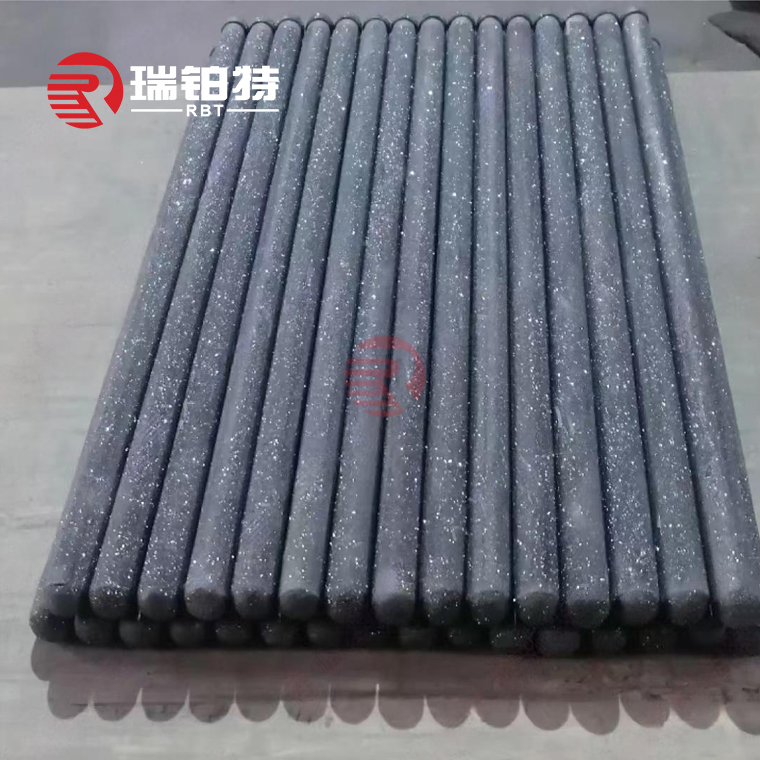

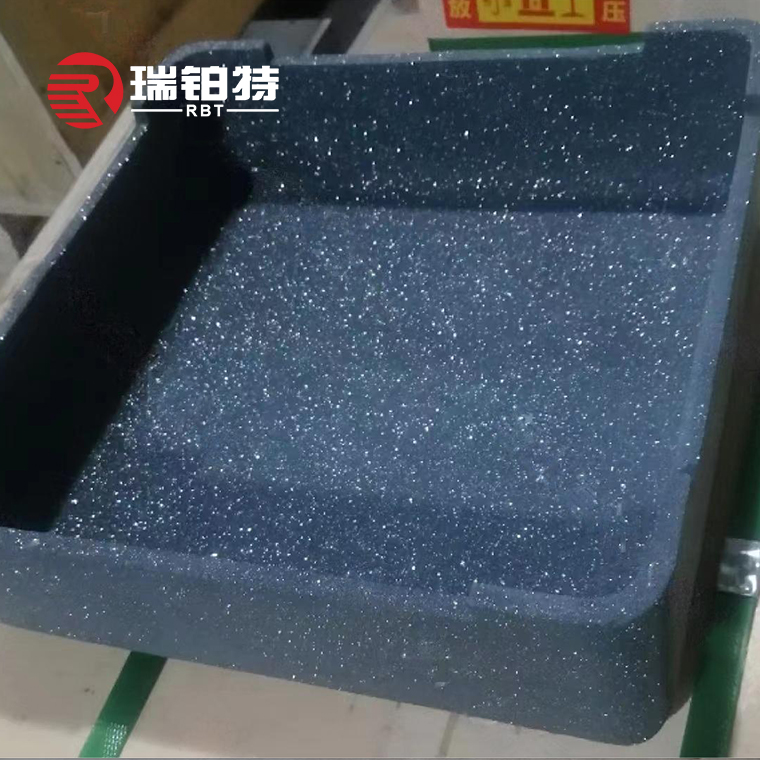

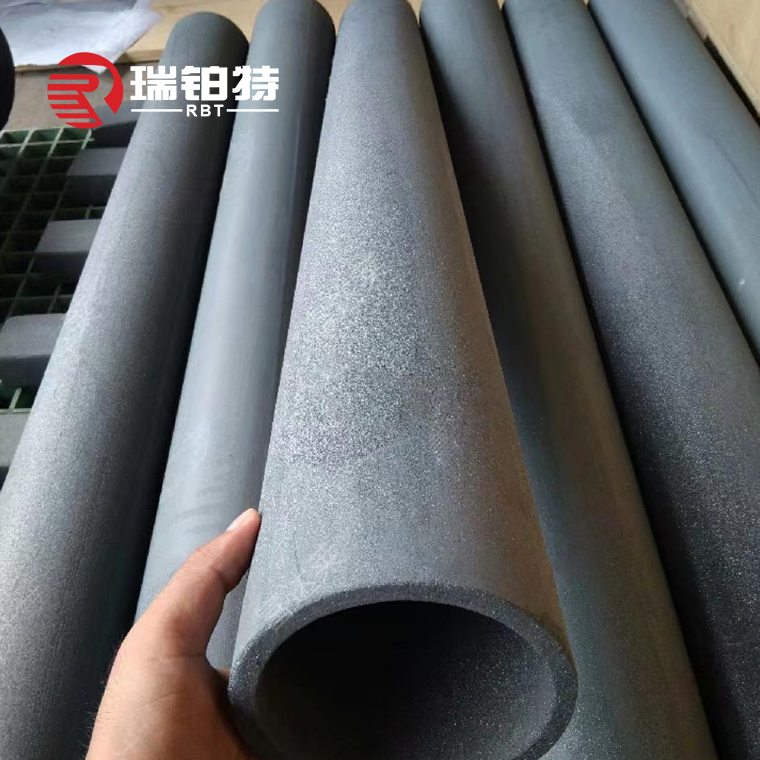

Dhuumaha carbide ee Silicon:loo isticmaalo tuubooyinka iyo weelasha ku yaal deegaan heerkul sare oo kala duwan. ?

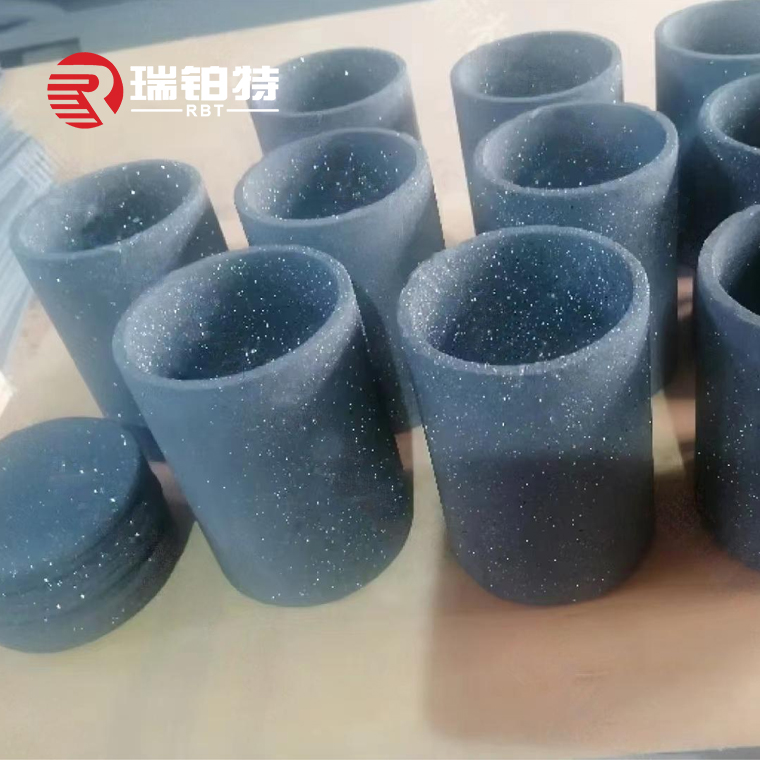

Silicon carbide crucible iyo sagger:loo isticmaalo dhalaalinta heerkulka sare iyo kaydinta agabka. ?

Giraanta silsiladda silikoon:si weyn loogu isticmaalo dhinacyada baabuurta, hawada hawada iyo warshadaha kiimikada, waxayna sii wadi kartaa wax qabad la isku halayn karo oo heerkul sare ah iyo jawi cadaadis sare ?

Rolalaha Silicon carbide:loo isticmaalo kilns rullaluistemadka ah, oo leh sifooyinka anti-oxidation, xoog dabacsanaan heerkul sarreeya iyo nolosha adeeg dheer. ?

Tuubooyinka qaboojinta Silicon carbide:loo isticmaalo aagga qaboojinta ee kilns rullaluistemadka, oo leh iska caabin wanaagsan oo xad dhaaf ah

qabow iyo kulayl. ?

Silicon carbide bunner bunner:loo isticmaalo saliidaha kala duwan, gaaska iyo kilnnada kale ee warshadaha, oo leh sifooyinka qabowga daran iyo caabbinta kulaylka, xidhashada caabbinta, caabbinta heerkulka sare, iwm. ?

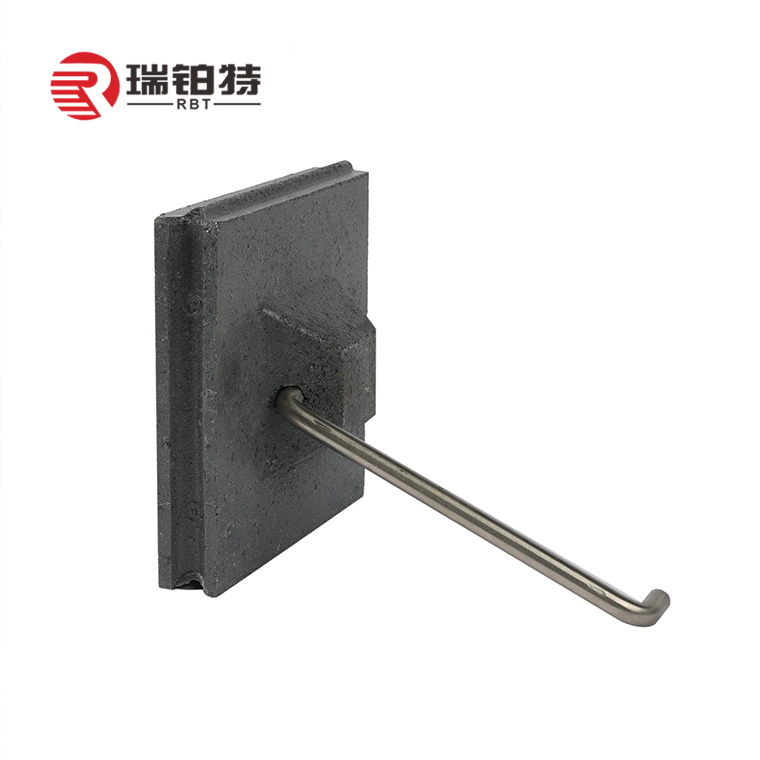

Qaybaha qaabaysan ee gaarka ah:Soo saarista la habeeyey ee qaybo kala duwan oo qaab gaar ah u qaabaysan iyadoo loo eegayo baahida macaamiisha, sida taarikada qaabka kalluunka, ulo laadlaadsan, qaybaha taageerada, iwm.

Faahfaahinta Sawirada

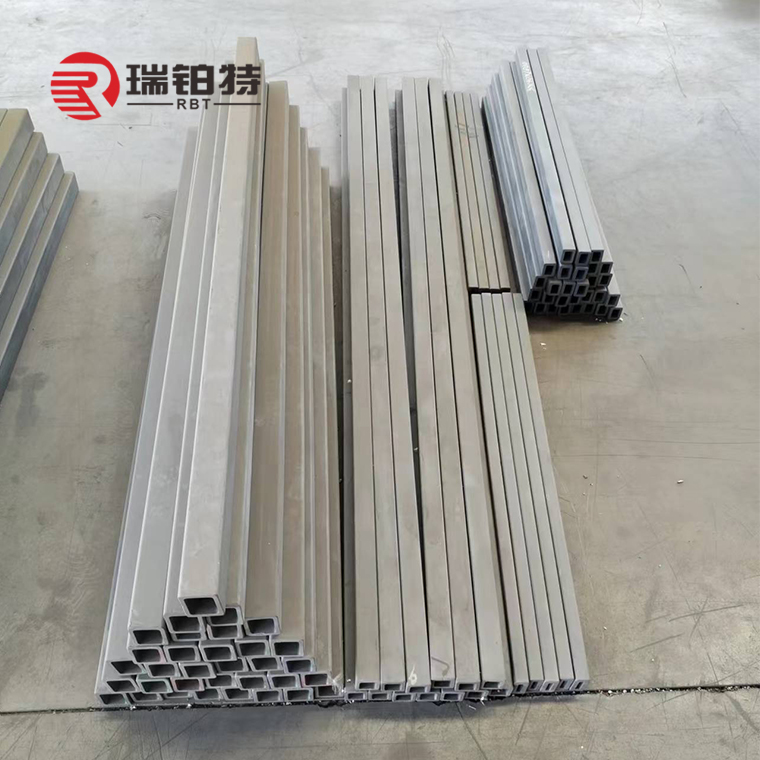

Silicon Carbide Beam

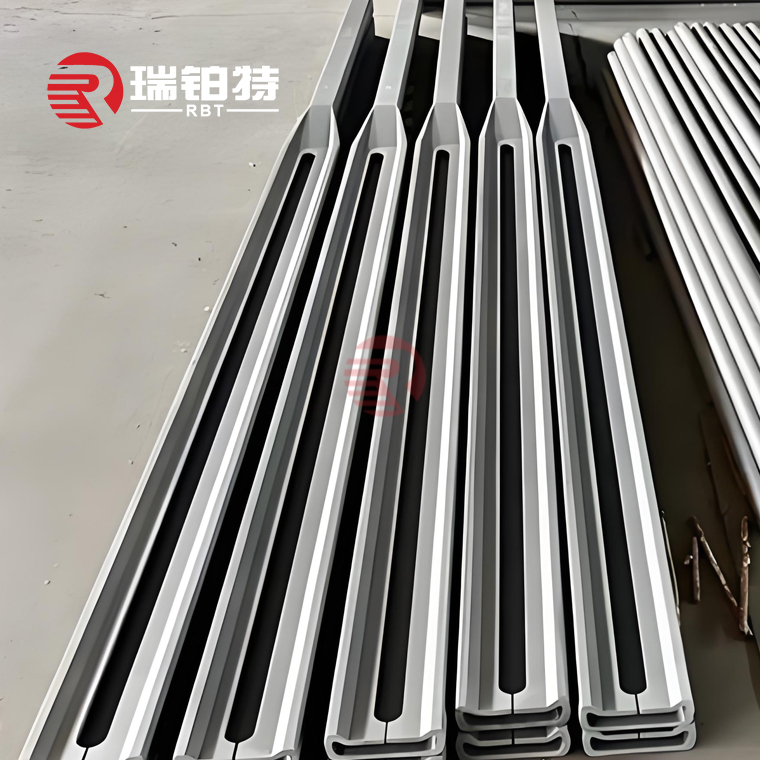

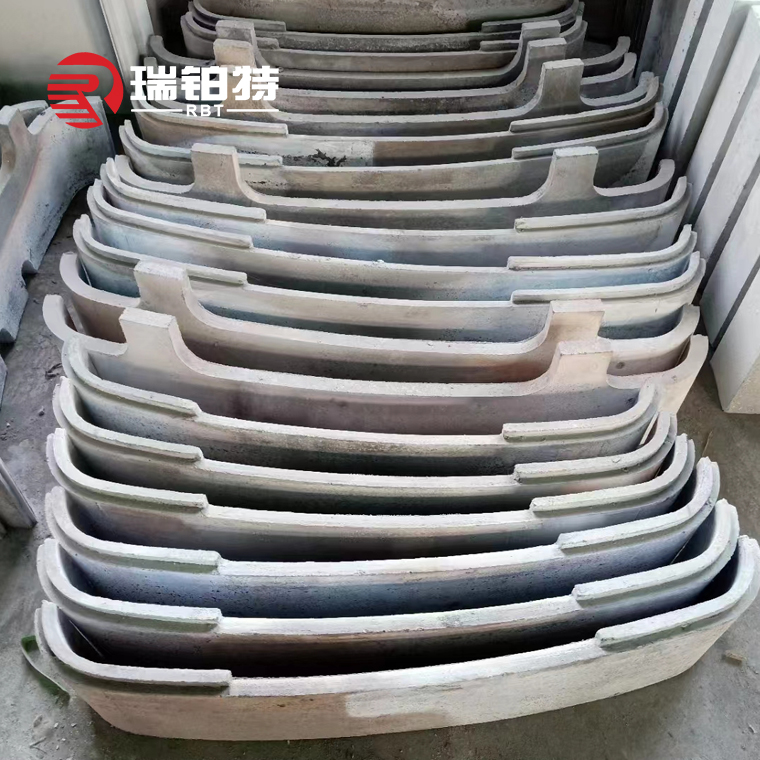

Silicon Carbide Cantilever Paddle

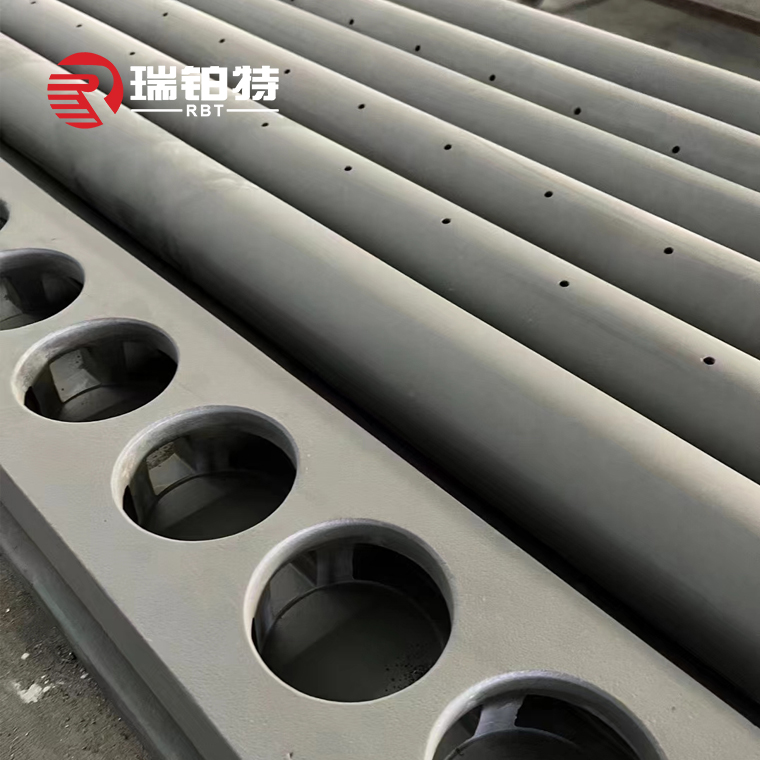

Silicon Carbide Nozzle

Silicon Carbide Burner Tube

Tubooyinka qaboojinta Silicon Carbide

Silicon Carbide Nozzle

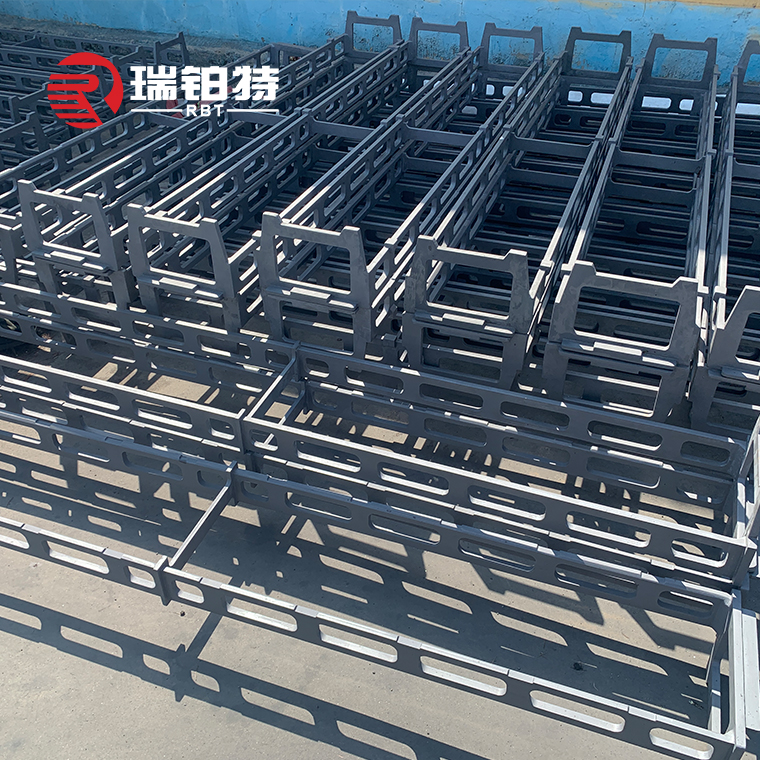

Garaafka Doonta Silicon Carbide

Dahaarka u adkaysta xidhashada

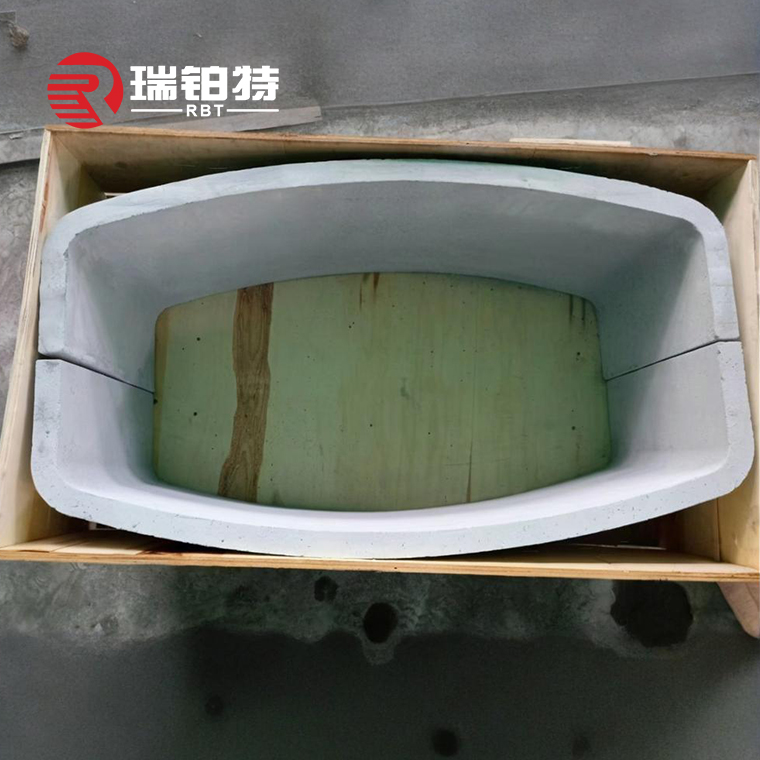

Silicon Carbide Wafer Doon

Tusmada Alaabta

| Alaabta RBSiC(SiSiC) | ||

| Shayga | Unug | Xogta |

| Heerkulka ugu badan ee Codsiga | ℃ | ≤1350 |

| Cufnaanta | g/cm3 | ≥3.02 |

| Porosity furan | % | ≤0.1 |

| Xoog Laabashada | Mpa | 250 (20 ℃); 280 (1200 ℃) |

| Hababka Elastictiy | Gpa | 330 (20 ℃); 300 (1200 ℃) |

| Habdhaqanka kulaylka | W/mk | 45 (1200 ℃) |

| Iskuxidhka Balaadhinta kulaylka | K-1*10-6 | 4.5 |

| Adagnimada Moh | | 9.15 |

| Acid Alkaline-Caddaynta | | Aad u fiican |

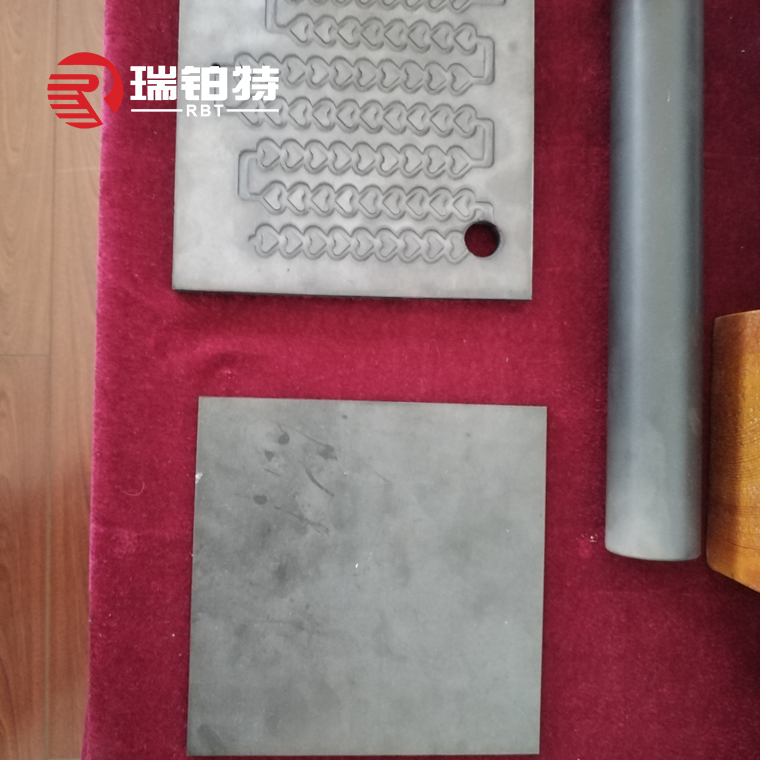

2. Alaabooyinka silikoon kaarbiide oo aan cadaadis lahayn (Alaabooyinka SSiC)

Alaabta carbide silikoon sintered Cadaad la'aan waa nooc ka mid ah walaxda dhoobada teknoolajiyada sare leh oo ay diyaarisay habsocod aan cadaadis lahayn. Qaybteeda ugu muhiimsan waa silikoon carbide (SiC), waxaana lagu daraa qayb gaar ah oo lagu daro. Iyada oo loo marayo tignoolajiyada hore ee dhoobada, waxaa laga sameeyaa dhoobada cufnaanta sare ee aan daloolin, aan tol lahayn, iyo walwal la'aan.

(1) Astaamaha:

Iska caabbinta heerkulka sare:isticmaalka caadiga ah ee 1800 ℃;

Dhaqdhaqaaqa kulaylka sare:oo u dhiganta hab-dhaqanka kulaylka ee garaafkaalaabta;

Adag sare:adayggu waxa uu ku xigaa dheeman iyo cubic boron nitride;

Iska caabbinta daxalka:Aashito xooggan iyo alkali xoog leh ma laha daxal, caabbinta daxalka ayaa ka fiican tan tungsten carbide iyo aluminium oxide;

Miisaanka fudud:cufnaanta 3.10g/cm3, ku dhow aluminium;

Wax qallafsanaan lahayn:isku xidhka ballaadhinta kulaylka oo aad u yar,

U adkaysta shoogga kulaylka:maaddadu waxay u adkeysan kartaa isbeddelada heerkulka degdega ah, shoogga kulaylka, qaboojinta degdega ah iyo kuleylka, waxayna leedahay waxqabad xasilloon.

(2) Alaabta ugu muhiimsan:

Silsilad-shabadeedka:Alaabooyinka kaarbiide silikoon oo aan cadaadis lahayn ayaa inta badan loo isticmaalaa si loo soo saaro xidhashada u adkaysta iyo daxalka u adkaysta siddooyinka xidhitaanka iyo biraha silbashada. ?

Qaybaha makaanikada:Oo ay ku jiraan xadhkaha kulaylka sareeyo, shaabadihii farsamada, sanbabada, alwaaxyada pneumatic, maydhka bamka, qalabyada, iwm.

Qalabka kiimikada:Loo isticmaalo in lagu sameeyo tuubooyinka u adkaysta daxalka, haamaha kaydinta, reactors iyo shaabadadaha. ?

Qalabka elegtarooniga ah:Warshadaha korantada, carbide silikoon aan cadaadis lahayn ayaa loo isticmaalaa in lagu soo saaro iska caabiyeyaasha kulaylka sareeyo, walxaha kuleylka korantada iyo furayaasha korantada sare. ?

Qalabka guriga ee kilka ah:Sida xargaha qaab dhismeedka xambaara, rollers, sanbabada ololka, tuubooyinka qaboojinta, iwm. ee ku jira foornada tunnel-ka, foornooyinka shuttles iyo kilnnada kale ee warshadaha. ?

Faahfaahinta Sawirada

Giraanta shaabadda ee Silicon Carbide

Dhuumaha Silicon Carbide

Qalabka Silicon Carbide

Silicon Carbide Beam

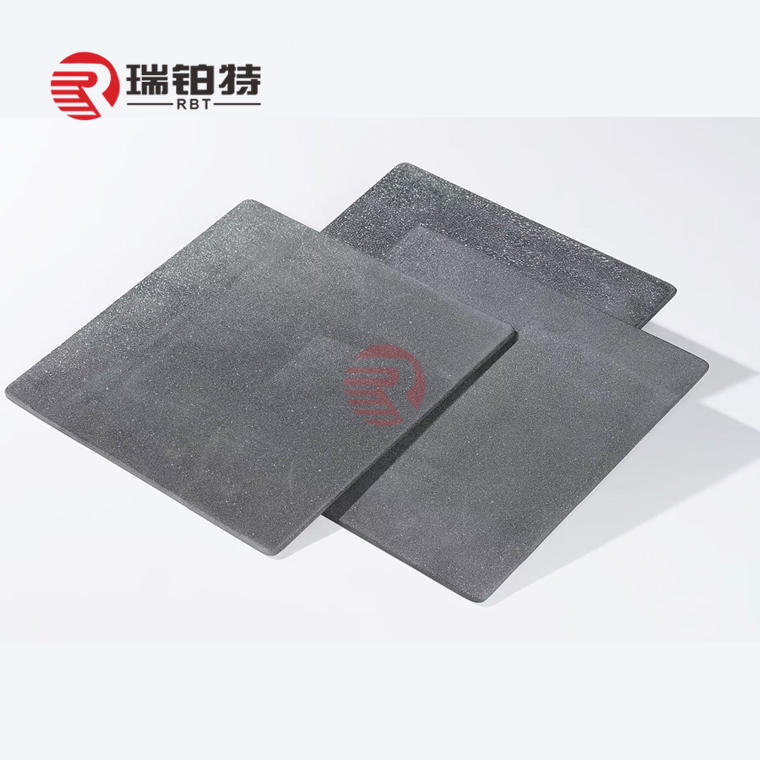

Silicon Carbide Plate

Foosto Shida Silicon Carbide

Tusmada Alaabta

| Alaabta SSIC | ||

| Shayga | Unug | Natiijada |

| Adag | HS | ≥115 |

| Heerka Porosity | % | <0.2 |

| Cufnaanta | g/cm3 | ≥3.10 |

| Xoog isku dhejisan | Mpa | ≥2500 |

| Xoog Laabashada | Mpa | ≥380 |

| Isku-dhafka Ballaarinta | 10-6/℃ | 4.2 |

| Nuxurka SiC | % | ≥98 |

| Si bilaash ah | % | <1 |

| Modulus Elastic | Gpa | ≥410 |

| Heerkulka ugu badan ee Codsiga | ℃ | 1400 |

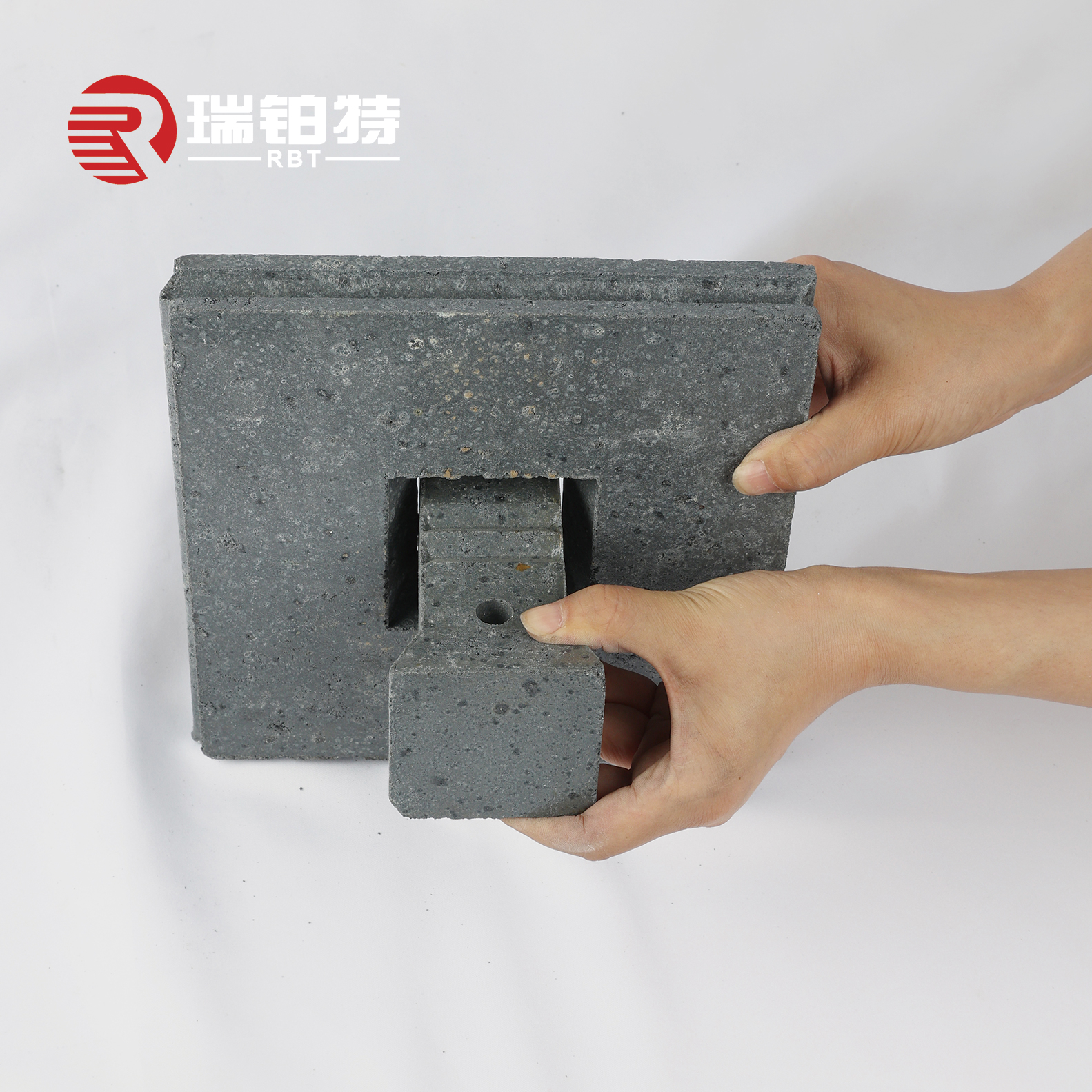

3. Alaabta carbide silikoon dib loo krishtay (Alaabada RSiC)

Alaabta Silicon-Carbide ee dib loo cusboonaysiiyay waa badeecad soo celinaysa oo ka samaysan karbide silikoon saafi ah oo saafi ah sida walxo ceeriin ah. Muuqaalkeeda ugu weyn waa in uusan jirin weji labaad oo ay ka kooban tahay 100% α-SiC.

(1) Astaamaha:

Adayg sare:Adaggeedu waxa uu ka hooseeyaa dheemanka oo keliya, waxana uu leeyahay xoog farsamo oo aad u sarreeya iyo qallafsanaan. ?

Iska caabbinta heerkulka sare:Waxay ilaalin kartaa waxqabadka xasilloon ee jawiga heerkulka sare waxayna ku habboon tahay heerkulka heerkulka 1350 ~ 1600℃. ?

Iska caabbinta daxalka xooggan:Waxay leedahay iska caabbinta daxalka sare ee warbaahinta kala duwan waxayna sii wadi kartaasifooyinka farsamada ee wakhti dheer meelo kala duwan oo daxalka ah. ?

Iska caabbinta oksaydheynta wanaagsan:Waxay leedahay iska caabin oksaydheyn oo wanaagsan waxayna si deggan ugu shaqayn kartaa heerkul sare ?

Iska caabbinta shoogga kulaylka wanaagsan:Waxay si fiican u qabataa jawi heerkulkiisu degdega yahay waxayna ku haboon tahay jawiga kulaylka. ?

Wax yareyn ma jiro inta lagu guda jiro sintering:Ma hoos u dhacdo inta lagu jiro habka sinterinta, iyo wax walbahaar ah oo hara ah lama dhalin doono si ay u keento qallafsanaan ama dildilaaca alaabta. Waxay ku habboon tahay diyaarinta qaybo leh qaabab adag iyo saxsanaan sare.

(2) Alaabta ugu muhiimsan:

Qalabka guriga ee kilka ah:Inta badan loo isticmaalo alaabta guriga, waxay leedahay faa'iidooyinka badbaadinta tamarta, kordhinta mugga wax ku oolka ah ee foornada, gaabinaysa wareegga rasaasta, hagaajinta waxtarka wax soo saarka foornada iyo faa'iidooyinka dhaqaale ee sarreeya. ?

Bunners-ka:Waxaa loo isticmaali karaa sidii madax biibiile oo gubanaysa waxayna ku habboon tahay jawiga heerkulka sare. ?

Tuubooyinka kuleylka shucaaca dhoobada:Tuubooyinka kuleyliyaha ayaa ka faa'iideysanaya xasilloonida heerkulka sare iyo iska caabinta daxalka ee carbide silicon recrystallized waxayna ku habboon yihiin codsiyada heerkulka sare ee kala duwan ee warshadaha. ?

Tuubooyinka ilaalinta qaybaha:Gaar ahaan foornooyinka jawiga, alaabada silikoon carbide ee dib loo soo celiyay ayaa loo isticmaalaa sida tuubooyinka ilaalinta ee leh heerkul sare oo wanaagsan iyo iska caabin daxalka. ?

Jidadka matoorka heer-kulka sarreeya, matoorada matoorka, xadhkaha, guryaha mishiinka:Goobaha baabuurta, hawada iyo warshadaha militariga, qalabka silikoon carbide recrystallized waxaa lagu sameeyaa maydh heerkulka sare, impellers bamka, biraha iyo guryaha engine, iwm, ka faa'iidaysanaya caabbinta heerkulka sare, acid iyo alkali iska caabin daxalka iyo xidho iska caabin ah. ?

Faahfaahinta Sawirada

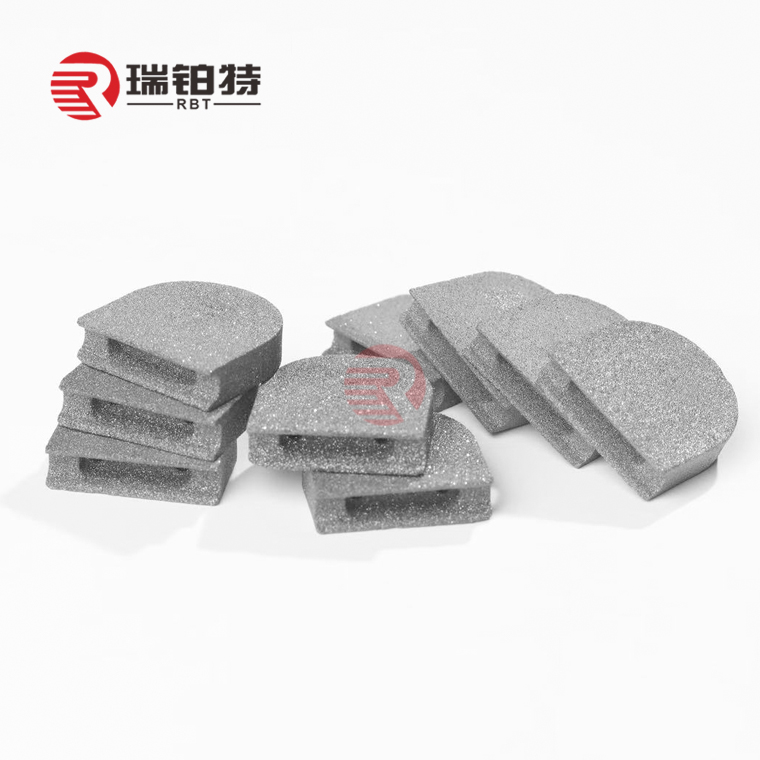

Qaybaha Qaabaysan Silicon Carbide

Silicon Carbide Plate

Roller Silicon Carbide

Silicon Carbide Beam

Tuubooyinka Ilaalinta Silicon Carbide

Furniture-ka

Silicon Carbide Sagger

Silicon Carbide Crucible

Silicon Carbide Plate

Silicon Carbide Lgniter

Dhuumaha Silicon Carbide

Silicon Carbide Gubida

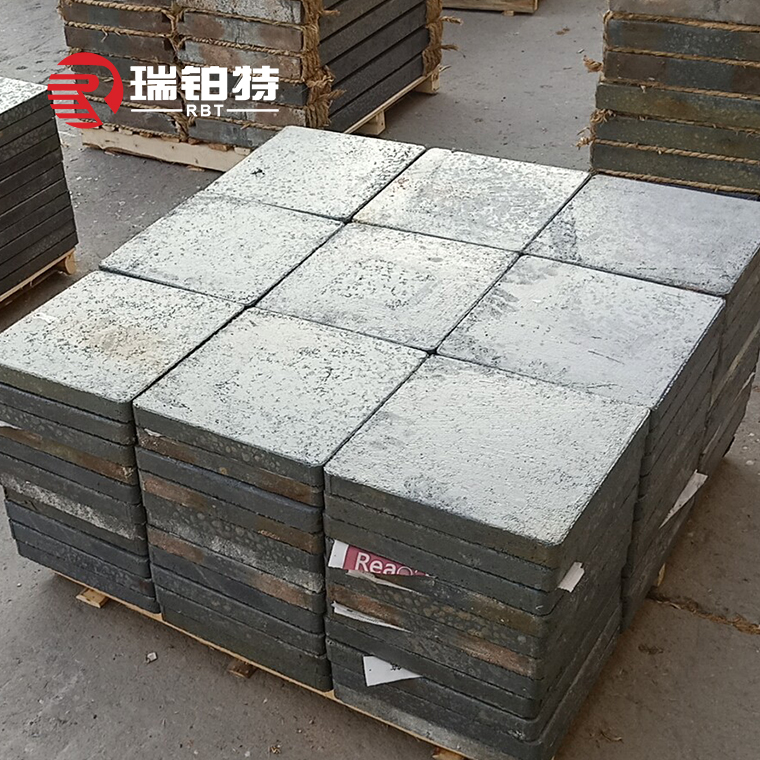

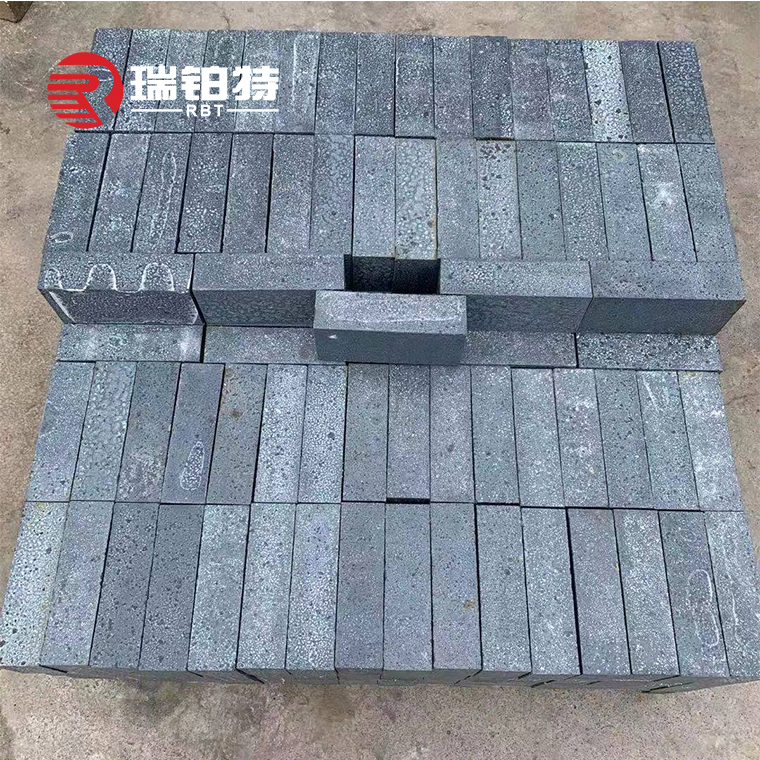

4. Alaabta silikoon nitride ku xidhan silikoon carbide(NSiC Products)

Silikon nitride-ku-xidhan alaabada silikoon carbide waa shay la sameeyay iyadoo lagu darayo wadarta guud ee SiC ee budada silikoonka warshadaha, ka falcelinta nitrogen heerkul sare si loo dhaliyo Si3N4 oo si adag la isugu daro qaybaha SiC.

(1) Astaamaha:

Adayg sare:Adkeydka Mohs ee alaabada silikoon nitride ku xidhan silikon carbide waxay ku saabsan tahay 9, labaad oo kaliya dheeman, waana shay leh engegnaan sare oo ka mid ah alaabta aan biraha ahayn. ?

Xoogga heerkulka sare:Heerkulka sare ee 1200-1400 ℃, xoogga iyo qallafsanaanta walaxda ayaa weli ah mid aan isbeddelin, iyo heerkulka isticmaalka ugu sarreeya wuxuu gaari karaa 1650-1750 ℃.

?

Deganaanshaha kulaylka:Waxay leedahay iskudhaf yar oo balaadhin kuleyl ah iyo kororka kulaylka sare, ma fududa in la dhaliyo walbahaarka kulaylka, waxay leedahay xasillooni shoog kulayl oo wanaagsan iyo iska caabin gurguurta, waxayna ku habboon tahay jawi aad u qabow iyo kulul. ?

Dejinta kiimikada:Waa u adkaysta daxalka iyo oksaydhaynta u adkaysta, waxayna ku ahaan kartaa mid deggan jawiyo kiimikaad oo kala duwan. ?

Xiro iska caabin:Waxay leedahay iska caabin xirxiran oo wanaagsan waxayna ku habboon tahay codsiyada warshadaha kala duwan ee leh daal daran.

(2) Alaabta ugu muhiimsan:

Lebenka dib-u-celinta:si weyn loogu isticmaalo aluminium elektrolytic ah, foornooyinka qaraxa birta-samaynta, foornooyinka arc-ka hoos jira iyo warshado kale, oo leh astaamaha iska caabbinta heerkulka sare, iska caabinta daxalka, iyo iska caabinta nabaadguurka.

Alaabta guriga:loo isticmaalo giraangiraha shiida dhoobada, foornada koronto-sare ee koronto, kilns warshadaha, iwm.

Alaabooyin qaabaysan:loo isticmaalo shubista birta ah ee aan birta ahayn, awoodda kulaylka, foornooyinka arc hoostooda iyo warshado kale, oo leh astaamaha caabbinta xirashada iyo iska caabinta heerkulka sare.

Qaybaha refractory:oo ay ku jiraan tuubooyinka ilaalinta kulaylka, tuubooyinka kor u kaca, gacmo kululaynta, iwm, oo loo isticmaalo kilns heerkulkiisu sarreeyo iyo jawi kala duwan, oo leh kulayl sare iyo caabbinta daxalka.

Faahfaahinta Sawirada

Saxanka Qaabaysan ee Silicon Carbide

Saxanka Qaabaysan ee Silicon Carbide

Saxanka Qaabaysan ee Silicon Carbide

Saxanka Qaabaysan ee Silicon Carbide

Saxanka Qaabaysan ee Silicon Carbide

Tuubooyinka Shucaaca Silicon Carbide

Dhuumaha Silicon Carbide

Saxanka Qaabaysan ee Silicon Carbide

Qaybaha Qaabaysan Silicon Carbide

Tuubooyinka Ilaalinta Silicon Carbide

Silicon Carbide Plate

Leben Silicon Carbide

5. Badeecadaha carbide silikoon ee oksaydh-ku-xidhan

Badeecadaha carbide silikoon-ku-xidhan ee oksaydhku waxa lagu sameeyaa iyadoo la isku qaso qaybo silikoon carbide ah iyo budada oksaydhka (sida silikoon dioxide ama mullite), riixaya oo ku shubaya heerkul sare. Dabeecaddeedu waa in inta lagu jiro habka sintering iyo isticmaalka, filimka oxide waxaa lagu duudduubay qaybaha silikoon carbide, taas oo si weyn u hagaajinaysa iska caabbinta oksaydhka iyo xoogga heerkulka sare.

Waxay leedahay sifooyinka xoogga dabacsanaanta heerkulka sare, xasilloonida shoogga kulaylka wanaagsan, kuleylka kuleylka sarreeya, xirashada caabbinta iyo caabbinta xooggan ee nabaadguurka jawiga kala duwan, waana wax ku habboon tamarta tamarta ee foornooyinka warshadaha.

(2) Alaabta ugu muhiimsan:

Alaabta silikoon dioxide ee ku xidhan silikoon carbide:Alaabtani waxay isticmaashaa silikoon dioxide (SiO2) sidii wejiga xidhitaanka. Caadiyan 5% ~ 10% budada Silicon dioxide ama budada quartz waxaa lagu qasaa qaybo silikoon carbide (SiC) ah. Mararka qaarkood qulqulitaan ayaa lagu daraa. Ka dib marka la cadaadiyo oo la sameeyo, waxaa lagu ridayaa foornada guud. Dabeecaddeeda ayaa ah in inta lagu jiro habka toogashada iyo isticmaalka, filimka silikoon dioxide waxaa lagu duubay qaybaha silikoon carbide, taas oo si weyn u wanaajisa iska caabbinta oksaydhka iyo xoogga heerkulka sare. Alaabtan waxaa si weyn loogu isticmaalaa khaanadaha foornada loogu talagalay in lagu shido dhoobada (> 1300 ℃), iyo nolosheeda adeeggu waa in ka badan

labanlaabmay tii alaabta silikoon carbide ku xidhan dhoobada. ?

Alaabooyinka carbide silikoon ee isku xidhan ee badan:Alaabtani waxay ku daraysaa budada α-Al2O3 iyo budada silikoon dioxide maaddooyinka silikoon carbide. Ka dib marka la cadaadiyo oo la sameeyo, Al2O3 iyo SiO2 ayaa la isku daraa si ay u sameeyaan mullite inta lagu jiro habka sintering. Inta lagu jiro isticmaalka, silikoon dioxide ka samaysan oksaydhka ee silikoon carbide qayb ahaan ka samaysan mullite leh Al2O3. Qalabkani wuxuu leeyahay xasillooni shoog kulayleed oo wanaagsan waxaana si weyn loogu isticmaalaa soo saarista saggers porcelain iyo khaanadaha.

Faahfaahinta Sawirada

Silicon Carbide Plate

Leben Silicon Carbide

Silicon Carbide Plate

SiC Microcrystalline Pipe

SiC Microcrystalline Board

SiC Microcrystalline Board

Xogta Shirkadda

Hal qayb oo ka mid ah Shandong Robert New Material Co., Ltd.Waxay ku taal magaalada Zibo, ee Gobolka Shandong, Shiinaha, oo ah saldhig wax-soo-saar walxo leh. Waxaan nahay shirkad casri ah oo midaysa cilmi-baarista iyo horumarinta, wax-soo-saarka, iibinta, naqshadeynta iyo dhismaha foornada, tignoolajiyada, iyo alaabada dib-u-celinta dhoofinta. Waxaan haysanaa qalab dhamaystiran, tignoolajiyada horumarsan, xoog farsamo oo xoog leh, tayada badeecada aad u fiican, iyo sumcad wanaagsan. Warshadayadu waxa ay dabooshaa in ka badan 200 oo hektar wax soo saarka sanadlaha ah ee agabka refractory-ku waa ku dhawaad 30000 oo tan iyo agabka refractory ee aan qaabaysani waa 12000 oo tan.

Alaabadayada ugu muhiimsan ee alaabta dib u soo celinta waxaa ka mid ah:walxaha dib-u-celinta alkaline; aluminium silikoon walxaha refractory; Walxaha dib-u-celinta ee aan qaabaysan; dahaarka alaabta refractory kulaylka; alaabta dib u celinta gaarka ah; agabka refractory functional ee hababka tuurista joogtada ah.

Su'aalaha Inta Badan La Isweydiiyo

Ma u baahan tahay caawimo? Hubi inaad booqato golayaasha taageerada jawaabaha su'aalahaaga!

Waxaan nahay soo saaraha dhabta ah, warshadeena waxay ku takhasustay soo saarista alaabta refractory in ka badan 30 sano. Waxaan ballan qaadaynaa inaan bixinno qiimaha ugu fiican, iibka hore ee ugu wanaagsan iyo adeegga iibka kadib.

Nidaam kasta oo wax soo saar ah, RBT waxay leedahay nidaam QC oo dhammaystiran oo loogu talagalay isku dhafka kiimikada iyo sifooyinka jirka. Anaguna waanu tijaabin doonaa alaabta, shahaadada tayada ayaa lagu rari doonaa alaabta. Haddii aad leedahay shuruudo gaar ah, waxaan isku dayi doonaa sida ugu fiican si aan u dejino.

Iyada oo ku xidhan tirada, wakhtiga dhalmadayadu way kala duwan tahay. Laakiin waxaan ballanqaadeynaa inaan sida ugu dhaqsaha badan ugu soo rari doonno tayada dammaanadda leh.

Dabcan, waxaanu bixinaa muunado bilaash ah.

Haa, dabcan, waxaa lagugu soo dhawaynayaa inaad booqato shirkadda RBT iyo alaabtayada.

Ma jiro wax xad ah, waxaan ku siin karnaa talada ugu fiican iyo xalka sida ay tahay xaaladdaada.

Waxaan samaynaynay qalab dib u celin ah in ka badan 30 sano, waxaan haysanaa taageero farsamo oo xoog leh iyo waayo-aragnimo qani ah, waxaan ka caawin karnaa macaamiisha inay naqshadeeyaan kilns kala duwan oo ay bixiyaan adeeg hal-joojin ah.