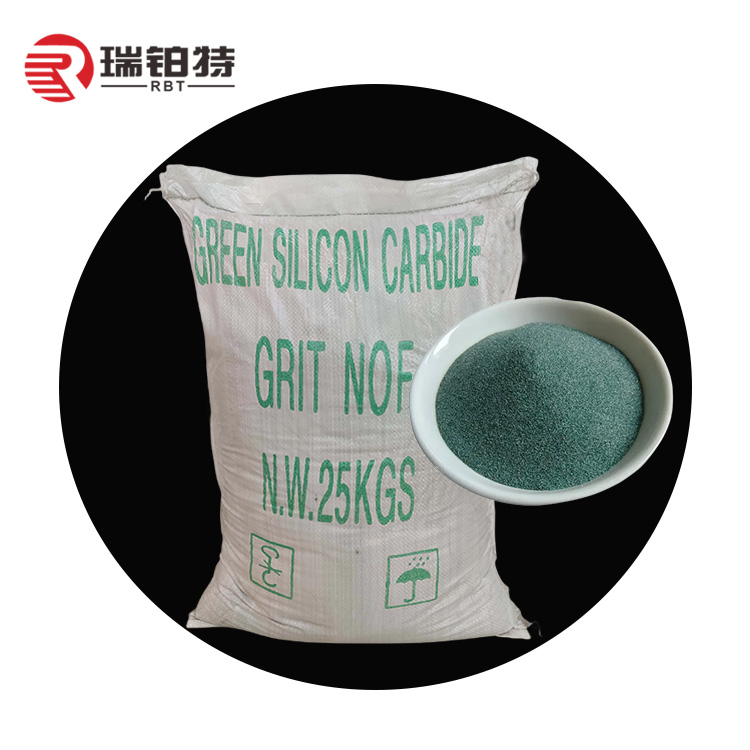

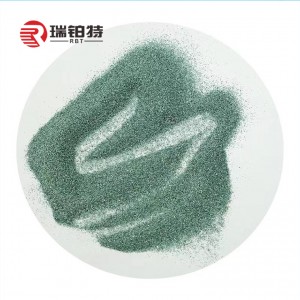

Silicon Carbide cagaaran

Macluumaadka Alaabta

| AlaabtaMagaca | Silicon Carbide cagaaran |

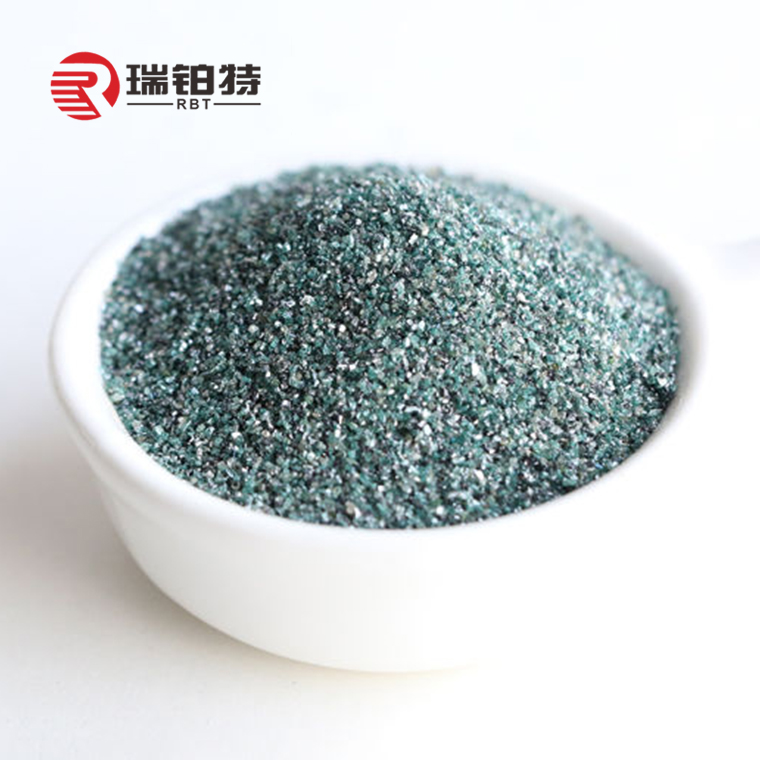

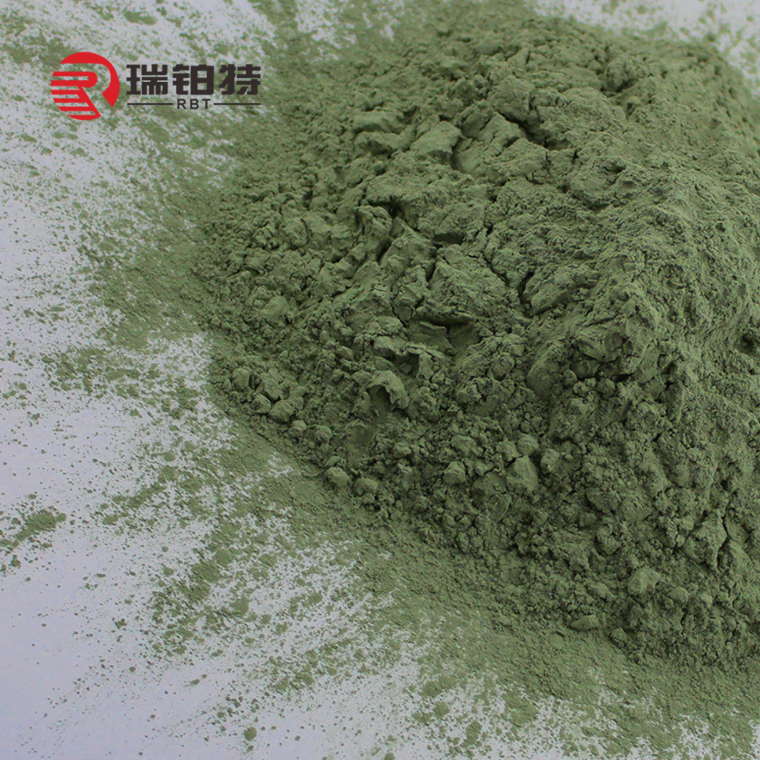

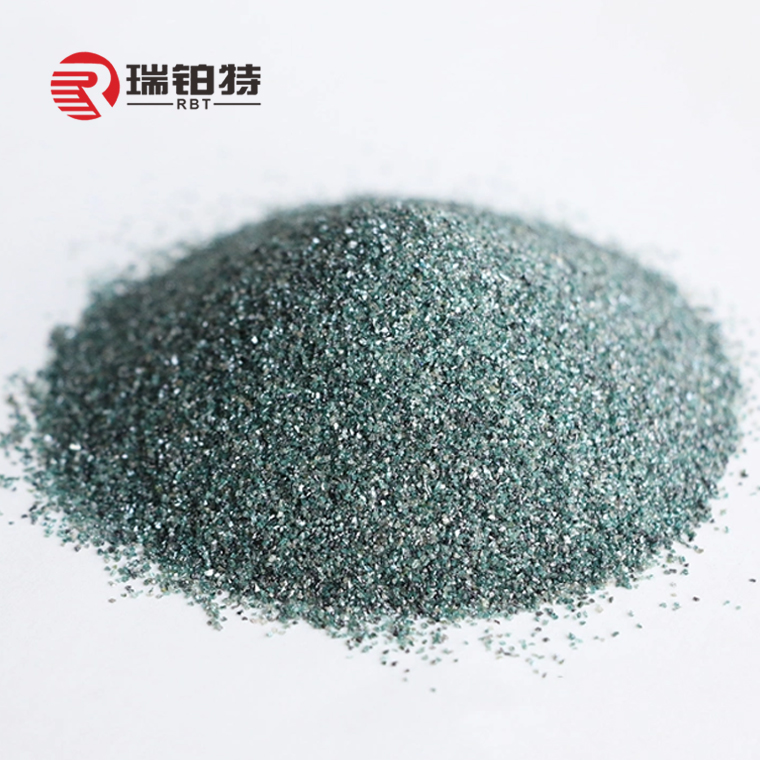

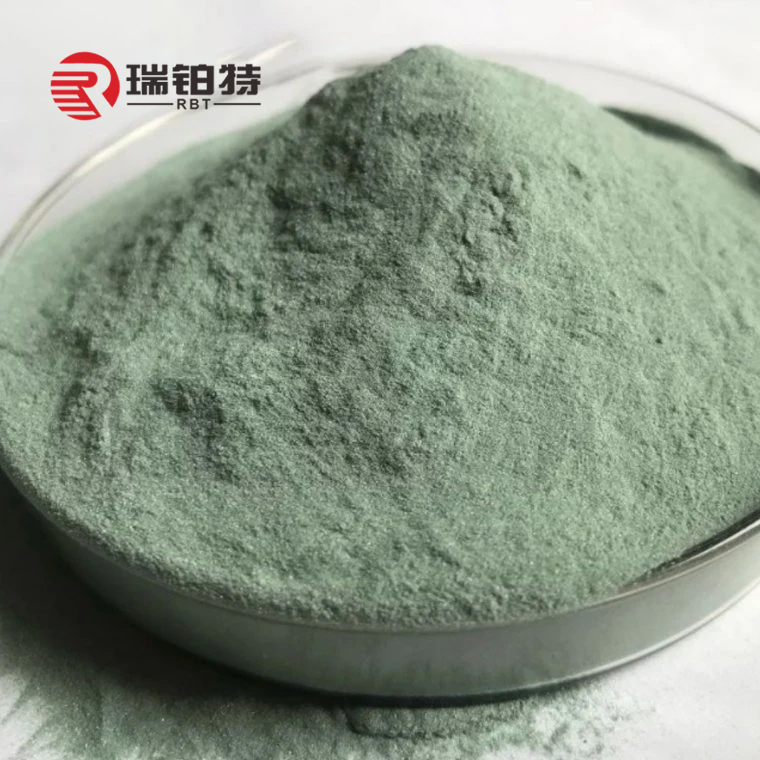

| Sharaxaada | Carbide silikoon cagaaran ayaa laga sameeyaa kookaha batroolka iyo silica tayada sare leh oo ah alaabta ceeriin ee ugu weyn, iyadoo cusbo lagu daro, waxaana lagu dhalaaliyaa heerkul sare oo foorno iska caabin ah.Waa crystal cagaaran, jilicsan oo fiiqan, waxayna leedahay kuleyl iyo korantada qaar. |

| Astaamaha | adkaanta sare ee 9.5 mohs;Nadiif Sare 98.5% Sic;Dhaqdhaqaaq kuleyl oo heer sare ah; Balaadhinta kulaylka hooseeya;Iska caabbinta sare ee asiidhka & beenta |

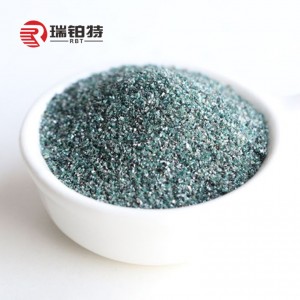

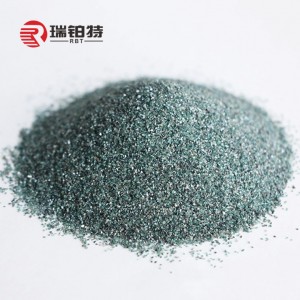

Guryaha Jirka

| Midabka | Cagaaran |

| Foomka Crystal | geeso badan |

| Mohs Hardness | 9.2-9.6 |

| Micro Hardness | 2840~3320kg/mm² |

| Meesha dhalaalaysa | 1723 |

| Heerkulka shaqada ee ugu badan | 1600 |

| Cufnaanta Dhabta ah | 3.21g/cm³ |

| Cufnaanta Bulk | 2.30g/cm³ |

Shaxda Isbarbardhigga Cabbirka Grit

| GritMaya | Shiinaha GB2477-83 | Japan JISR 6001-87 | USA ANSI(76) | 欧洲磨料协 FEPA(84) | 国际 ISO(86) |

| 4 | 5600-4750 | | 5600-4750 | 5600-4750 | 5600-4750 |

| 5 | 4750-4000 | | 4750-4000 | 4750-4000 | 4750-4000 |

| 6 | 4000-3350 | | 4000-3350 | 4000-3350 | 4000-3350 |

| 7 | 3350-2800 | | 3350-2800 | 3350-2800 | 3350-2800 |

| 8 | 2800-2360 | 2800-2360 | 2800-2360 | 2800-2360 | 2800-2360 |

| 10 | 2360-2000 | 2360-2000 | 2360-2000 | 2360-2000 | 2360-2000 |

| 12 | 2000-1700 | 2000-1700 | 2000-1700 | 2000-1700 | 2000-1700 |

| 14 | 1700-1400 | 1700-1400 | 1700-1400 | 1700-1400 | 1700-1400 |

| 16 | 1400-1180 | 1400-1180 | 1400-1180 | 1400-1180 | 1400-1180 |

| 20 | 1180-1000 | 1180-1100 | 1180-1000 | 1180-1000 | 1180-1000 |

| 22 | 1000-850 | - | - | 1000-850 | 1000-850 |

| 24 | 850-710 | 850-710 | 850-710 | 850-710 | 850-710 |

| 30 | 710-600 | 710-600 | 710-600 | 710-600 | 710-600 |

| 36 | 600-500 | 600-500 | 600-500 | 600-500 | 600-500 |

| 40 | 500-425 | - | - | 500-425 | 500-425 |

| 46 | 425-355 | 425-355 | 425-355 | 425-355 | 425-355 |

| 54 | 355-300 | 355-300 | 355-297 | 355-300 | 355-300 |

| 60 | 300-250 | 300-250 | 297-250 | 300-250 | 300-250 |

| 70 | 250-212 | 250-212 | 250-212 | 250-212 | 250-212 |

| 80 | 212-180 | 212-180 | 212-180 | 212-180 | 212-180 |

| 90 | 180-150 | 180-150 | 180-150 | 180-150 | 180-150 |

| 100 | 150-125 | 150-125 | 150-125 | 150-125 | 150-125 |

| 120 | 125-106 | 125-106 | 125-106 | 125-106 | 125-106 |

| 150 | 106-75 | 106-75 | 106-75 | 106-75 | 106-75 |

| 180 | 90-63 | 90-63 | 90-63 | 90-63 | 90-63 |

| 220 | 75-53 | 75-53 | 75-53 | 75-53 | 75-53 |

| 240 | 75-53 | - | 75-53 | - | |

Faahfaahinta Sawirada

Tusmada Alaabta

| Cabbirka grit | Halabuurka Kiimikada% (Miisaan ahaan) | ||

| SIC | F·C | Fe2O3 | |

| 12#-90# | ≥98.50 | ≤0.20 | ≤0.60 |

| 100#-180# | ≥98.00 | ≤0.30 | ≤0.80 |

| 220#-240# | ≥97.00 | ≤0.30 | ≤1.20 |

| W63-W20 | ≥96.00 | ≤0.40 | ≤1.50 |

| W14-W5 | ≥93.00 | ≤0.40 | ≤1.70 |

Codsiga

1. Waxyeelo leh:Carbide silikoon cagaaran ayaa si weyn loogu isticmaalaa walxo xoqid ah warshadaha kala duwan, oo ay ku jiraan baabuurta, hawada hawada, biraha, iyo dahabka.Waxa loo isticmaalaa shiididda, jarista, iyo turxaan bixinta biraha adag iyo dhoobada.

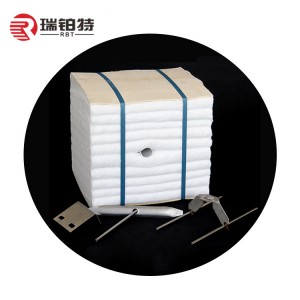

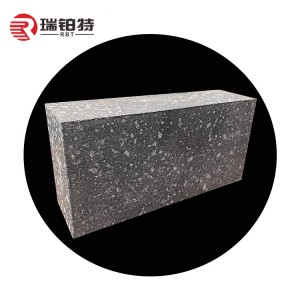

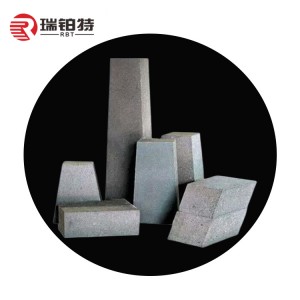

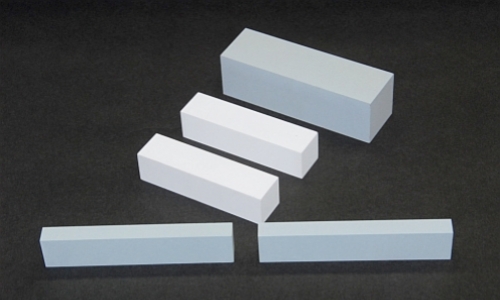

2. Refractory:Carbide silikoon cagaaran ayaa sidoo kale loo isticmaalaa walxo celinaya codsiyada kulaylka sare leh sida foornooyinka iyo kilnsyada sababtoo ah kuleylka sare ee kuleylka iyo ballaarinta kulaylka hooseeya.

3. Elektrooniga:Carbide silikoon cagaaran waxaa loo isticmaalaa sida walxo substrate ah oo loogu talagalay aaladaha elektiroonigga ah sida LED-yada, aaladaha korantada, iyo aaladaha microwave-ka iyadoo ay ugu wacan tahay korantada wanaagsan ee ay leedahay iyo xasilloonida kuleylka.

4. Tamarta qorraxda:Carbide silikoon cagaaran ayaa loo isticmaalaa sidii qalab loogu talagalay soo saarista muraayadaha qoraxda sababtoo ah kuleylkeeda sare ee kuleylka iyo ballaarinta kulaylka hooseeya, taas oo gacan ka geysaneysa baabi'inta kulaylka soo baxa inta lagu jiro hawlgalka muraayadaha qorraxda.

5. Metallurgy:Carbide silikoon cagaaran waxaa loo isticmaalaa sida wakiilka deoxidizing ee soo saarista birta iyo birta.Waxay kaa caawinaysaa in wasakhda laga saaro birta dhalaalaysa iyo hagaajinta tayada alaabta ugu dambaysa.

6. Ceramics:Carbide silikoon cagaaran waxaa loo isticmaalaa sida walxo ceeriin ah oo loogu talagalay soo saarista dhoobada horumarsan sida qalabka goynta, qaybaha xirashada, iyo qaybaha heerkulka sare sababtoo ah qallafsanaantiisa sare, xoog badan, iyo xasilloonida kulaylka aadka u fiican.

Xidhmada&Bakhaarka

| Xidhmada | 25KG boorso | 1000KG Shandad |

| Tirada | 24-25 tan | 24 tan |

Su'aalaha Inta Badan La Isweydiiyo

Ma u baahan tahay caawimo?Hubi inaad booqato golayaasha taageerada jawaabaha su'aalahaaga!

Waxaan nahay soo saaraha dhabta ah, warshadeena waxay ku takhasustay soo saarista alaabta refractory in ka badan 30 sano.Waxaan ballan qaadaynaa inaan bixinno qiimaha ugu fiican, iibka hore ee ugu wanaagsan iyo adeegga iibka kadib.

Nidaam kasta oo wax soo saar ah, RBT waxay leedahay nidaam QC oo dhammaystiran oo loogu talagalay isku dhafka kiimikada iyo sifooyinka jirka.Oo waanu tijaabin doonaa alaabta, shahaada tayada ayaa lagu rari doonaa alaabta.Haddii aad leedahay shuruudo gaar ah, waxaan isku dayi doonaa sida ugu fiican si aan u dejino.

Iyada oo ku xidhan tirada, wakhtiga dhalmadayadu way kala duwan tahay.Laakiin waxaan ballanqaadeynaa inaan sida ugu dhaqsaha badan ugu soo dejinno tayada dammaanadda leh.

Dabcan, waxaanu bixinaa muunado bilaash ah.

Haa, dabcan, waxaa lagugu soo dhawaynayaa inaad booqato shirkadda RBT iyo alaabtayada.

Ma jiro wax xaddidan, waxaan ku siin karnaa talada ugu fiican iyo xalka sida ay tahay xaaladdaada.

Waxaan samaynaynay qalab dib u celin ah in ka badan 30 sano, waxaan haysanaa taageero farsamo oo xoog leh iyo waayo-aragnimo qani ah, waxaan ka caawin karnaa macaamiisha inay naqshadeeyaan kilns kala duwan oo ay bixiyaan adeeg hal-joojin ah.